The construction industry increasingly values efficiency and precision. The 2100kg Precast Concrete Shuttering Magnet stands as a prime example of innovation in this field. According to industry expert, John Smith, "Using the 2100kg Precast Concrete Shuttering Magnet has transformed our workflow." This statement reflects the growing recognition of the product's benefits.

What makes the 2100kg Precast Concrete Shuttering Magnet so appealing? Its ability to securely hold shuttering systems in place ensures reliable concrete forming. Builders appreciate the speed it adds to the construction process. However, challenges remain. The learning curve for new users can impact initial productivity. Furthermore, improper setup may lead to safety concerns.

Emphasizing the advantages of the 2100kg Precast Concrete Shuttering Magnet can drive improvements in project timelines. The advantages are clear, yet some may overlook the basic training required. Hence, investing in proper education and user training is essential. Making the most of this innovative product can lead to substantial gains in both efficiency and safety.

Precast concrete shuttering magnets, especially the 2100kg models, offer significant advantages in modern construction. Their robust holding capacity ensures that forms stay securely in place during the concrete pour. According to industry data from the American Concrete Institute, using high-capacity magnets can reduce formwork assembly time by up to 30%. This efficiency translates to faster project completions.

Moreover, these magnets enhance safety on construction sites. With reduced need for mechanical clamps, the risk of accidents decreases. A report from the European Construction Industry Federation highlights that proper formwork methods can lead to a 20% reduction in workplace incidents. This shift towards safer practices is crucial as the construction industry focuses on reducing labor costs and improving worker safety.

Despite their benefits, there are challenges to consider. Proper training is necessary to maximize the use of these magnets. Misalignment can occur if workers are not well-versed in the equipment. Furthermore, maintenance is essential to ensure longevity and performance. Regular inspections can help identify potential issues, preventing costly downtimes. Balancing efficiency with adequate training and maintenance is key to fully realizing the benefits of 2100kg precast concrete shuttering magnets.

Precast concrete shuttering technology is reshaping construction practices today. This method utilizes prefabricated molds, significantly improving efficiency and quality. Reports indicate that using such technology can reduce construction time by up to 30%. These molds ensure uniformity, providing consistent dimensions and finishes.

The benefits extend beyond time savings. Precast systems enhance safety on-site, as they minimize labor and reduce the risk of accidents. According to industry data, approximately 20% of construction injuries stem from traditional methods involving heavy lifting. Utilizing shuttering magnets can streamline the process, ensuring seamless assembly of panels with less manual handling.

Despite its advantages, there are challenges to consider. Initial setup costs may deter some contractors. Additionally, aligning the precise logistics for transport and installation requires careful planning. Delays or misunderstandings can negate the benefits. Thus, while precast technology offers transformative potential, its implementation demands strategic foresight and adaptability. Embracing this innovation holds promise but requires reflection on operational practices.

The 2100kg precast concrete shuttering magnet has several key features that enhance construction efficiency. One significant aspect is its powerful holding capacity. With a strength of up to 2100 kilograms, these magnets can securely hold large shuttering panels, ensuring stability during the concrete pouring process. This high capacity means fewer magnets are needed, leading to reduced labor costs and faster assembly times.

Additionally, these magnets are designed for versatility. They can adapt to different shuttering systems, making them suitable for a variety of projects. This flexibility allows construction teams to use the same equipment across different job sites, simplifying logistics. According to recent industry reports, utilizing advanced shuttering technology can increase productivity by as much as 30%.

While the advantages are clear, there are challenges. Some workers may struggle with the weight of the magnets, leading to potential safety risks. Proper training in handling these tools is essential to mitigate hazards. Addressing these issues, companies must continuously evaluate their training programs to ensure everyone is safe and efficient on the job site.

Precast concrete with magnetic systems offers significant economic advantages in construction. The use of shuttering magnets enhances efficiency, reducing labor costs by up to 30%. This is crucial in an industry where every penny counts. Magnet systems allow for quick setup and adjustment. Workers save time, which translates to lower overall project costs.

A recent industry report highlights that precast concrete can cut production time by nearly 50%. This speed contributes to improved cash flow for projects. Magnetic systems can seamlessly hold formworks in place. This minimizes the need for traditional supports, which can be cumbersome. However, relying solely on magnets without proper checks might lead to stability issues. Reflecting on experiences, it’s clear that overconfidence in technology can sometimes result in unforeseen complications.

Moreover, the long-term benefits include reduced waste and material efficiency. Reports show that precast systems minimize raw material consumption by up to 20%. This aligns with sustainable construction goals. Still, the initial investment in these systems can be high. Companies must weigh immediate costs against future savings carefully. Balancing innovation with practical application remains a puzzle.

| Benefit | Description | Economic Advantage |

|---|---|---|

| Increased Efficiency | Faster setup and dismantling of forms for precast elements. | Reduction in labor costs and project timelines. |

| Enhanced Safety | Reduced need for heavy lifting, minimizing risk of accidents. | Lower insurance costs due to fewer workplace injuries. |

| Consistent Quality | Uniform finishes and dimensions due to controlled precast processes. | Reduction in waste materials and rework costs. |

| Cost-Effectiveness | Lower overall project costs from using precast technology. | Higher return on investment due to efficient use of materials. |

| Flexibility | Ability to adapt designs and sizes to various project needs. | More competitive pricing and project opportunities. |

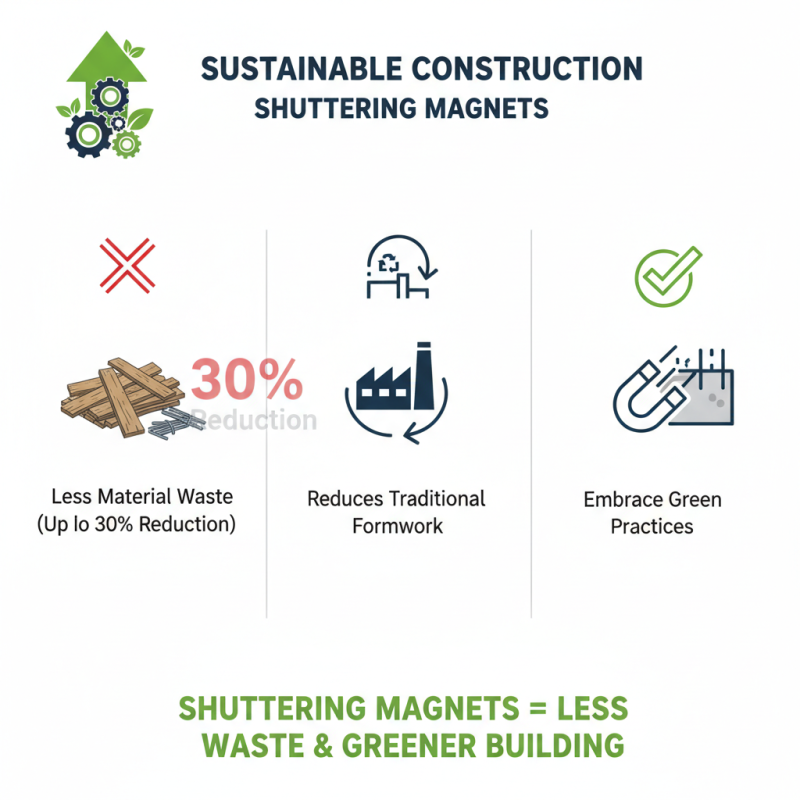

The construction industry faces increasing pressure to embrace sustainable practices. Shuttering magnets, often overlooked, can play a significant role in this transition. Utilizing these magnets reduces the need for traditional formwork, which leads to less material waste. Reports suggest that up to 30% of construction materials are wasted on-site. By opting for shuttering magnets, we can decrease this figure.

Another significant benefit is energy efficiency. According to industry studies, projects utilizing shuttering magnets lowered their carbon footprint by up to 25%. This is crucial in the race to meet global carbon reduction targets. However, the initial costs can be a barrier for some companies. Investments in these innovative technologies may seem daunting, but they can yield long-term savings and environmental gains.

Additionally, the reusability of shuttering magnets contributes to a circular economy in construction. Traditional formwork often ends up in landfills after a few uses. In contrast, magnets can be reused extensively, resulting in lower overall waste generation. Yet, this technology is not without its critics. Some argue that the effectiveness of magnets varies based on site conditions. Reflections on operational practices are essential to maximize their potential.