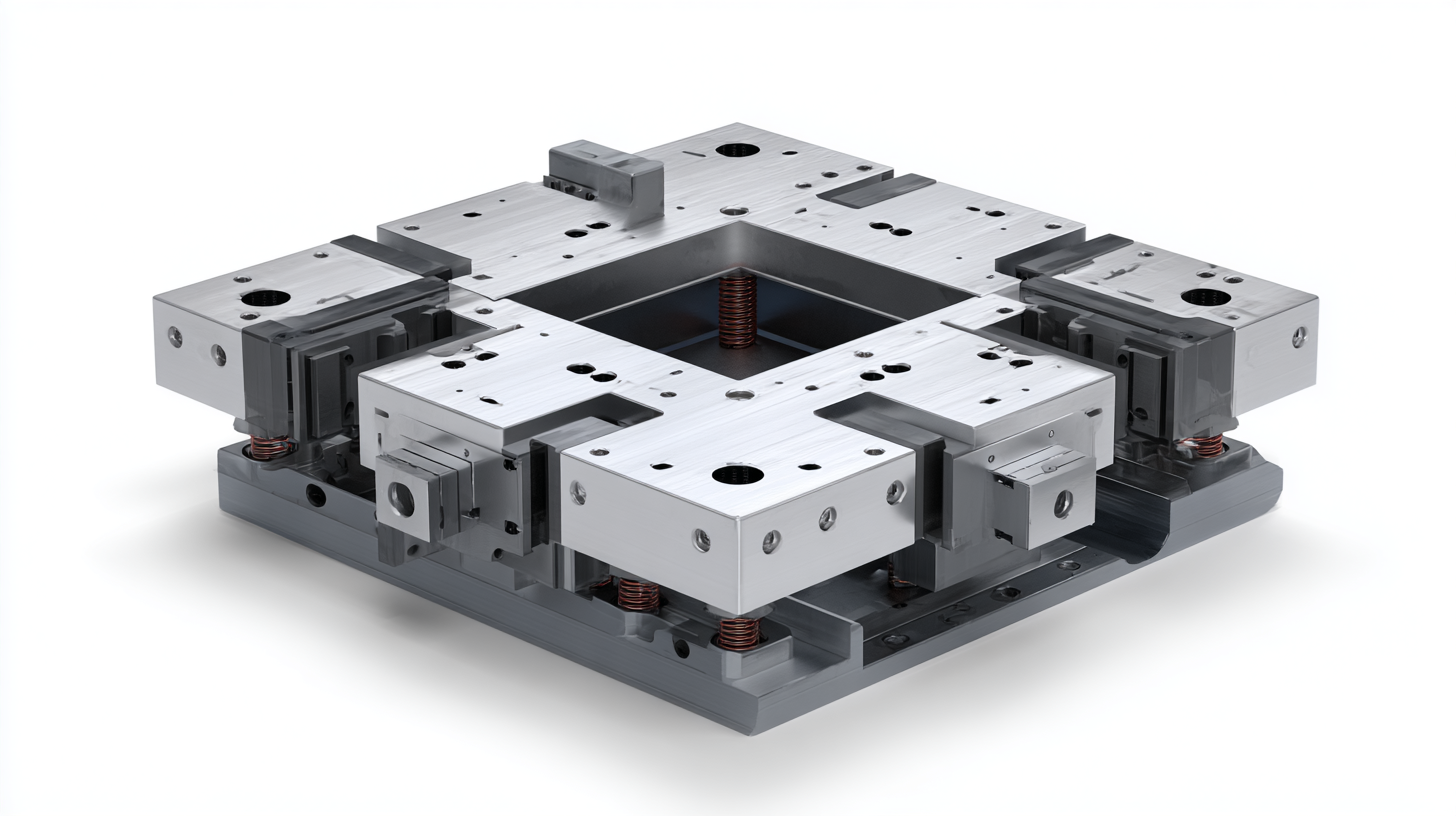

In the ever-evolving landscape of construction technology, the importance of utilizing efficient and innovative tools cannot be overstated. Among these advancements, the Electric Box Insert Magnet for precast concrete production stands out as a game-changer, offering a multitude of advantages that streamline operations and enhance product quality.

By integrating electric box insert magnets into the precast concrete process, manufacturers can achieve greater precision in the placement of electrical boxes, significantly reducing labor costs and time. This innovation not only improves the overall efficiency of the production line but also ensures that the finished products meet rigorous industry standards.

As the market heads toward 2025, understanding the unique benefits of electric box insert magnets will be crucial for companies aiming to enhance their competitive edge and produced quality in precast concrete manufacturing.

In this blog, we will delve into the numerous advantages these magnets offer, supported by examples from industry leaders who have successfully adopted this technology.

By integrating electric box insert magnets into the precast concrete process, manufacturers can achieve greater precision in the placement of electrical boxes, significantly reducing labor costs and time. This innovation not only improves the overall efficiency of the production line but also ensures that the finished products meet rigorous industry standards.

As the market heads toward 2025, understanding the unique benefits of electric box insert magnets will be crucial for companies aiming to enhance their competitive edge and produced quality in precast concrete manufacturing.

In this blog, we will delve into the numerous advantages these magnets offer, supported by examples from industry leaders who have successfully adopted this technology.

The utilization of electric box insert magnets in precast concrete offers significant advantages, particularly in enhancing the stability and strength of the final products. According to a report by the National Precast Concrete Association, the use of advanced magnet systems allows for a more precise alignment and positioning of electrical boxes during the casting process. This improved accuracy not only minimizes the chances of defects but also optimizes the integrity of the concrete structures, ensuring they withstand the forces they encounter during their lifespan.

Moreover, the magnetic insert solutions significantly reduce the potential for cracking and other structural failures by providing additional support where it matters most. A study published in the Journal of Structural Engineering indicates that precast components incorporating electric box insert magnets exhibit an increase in load-carrying capacity by up to 20%. This increase in strength is crucial for applications in high-load environments, reassuring engineers and builders of the durability and reliability of their constructions. The advantages of using these innovative magnets extend beyond mere convenience; they are a pivotal factor in pushing the boundaries of what precast concrete can achieve in modern construction.

The use of electric box insert magnets in precast concrete has been shown to significantly enhance construction efficiency and reduce time spent on site. According to a report by the National Precast Concrete Association, the integration of these magnets can streamline the installation process by up to 30%. This is largely due to their ability to securely hold electrical boxes in place during the curing process, minimizing the need for manual adjustments and ensuring precise positioning. This not only expedites assembly but also improves the overall quality of the installation.

Moreover, studies indicate that the deployment of electric box insert magnets allows for a reduction in labor costs, which can constitute up to 15% of the total project budget. By minimizing the amount of time workers spend on tasks related to electrical box installation, construction teams can allocate their resources more effectively. As a result, projects are completed faster, and companies are better positioned to take on additional jobs, ultimately yielding higher profit margins. These advantages make electric box insert magnets a vital innovation in the precast concrete industry, underscoring the importance of adopting advanced technologies for improved operational efficiencies.

When considering the use of high-quality electric box insert magnets in precast concrete, a cost-benefit analysis reveals significant long-term savings. Research indicates that utilizing superior magnet technology can enhance installation efficiency, leading to labor cost reductions of up to 20%. This efficiency not only minimizes the labor hours needed for setups but also greatly reduces the risk of errors during the installation process, further streamlining operations and saving costs.

Furthermore, the durability of these advanced magnets offers a substantial return on investment. Studies show that high-quality electric box insert magnets can withstand harsh environmental conditions, resulting in a lifespan that is 30% longer than traditional options. This longevity decreases the frequency of replacements and repairs, leading to additional maintenance savings over time. With the construction industry facing increasing pressure to minimize costs and enhance sustainability, choosing the best electric box insert magnets emerges as a strategic decision that aligns with both financial and operational objectives.

The use of electric box insert magnets in precast concrete not only streamlines the construction process but also significantly enhances safety during assembly. One of the primary risks in precast concrete assembly is the potential for injury from improperly placed electrical boxes, which can lead to containment issues and dangerous working conditions. By integrating electric box inserts, construction teams can ensure that all electrical components are securely positioned, minimizing the risk of accidents caused by loose or misaligned boxes.

Moreover, electric box insert magnets facilitate a more efficient workflow. These inserts allow for quick adjustments during assembly, enabling workers to reposition boxes with ease. This adaptability is crucial in maintaining a safe working environment because it reduces the need for manual handling of heavy components, thereby decreasing the likelihood of strain or injury. Ultimately, the strategic use of electric box insert magnets not only promotes a safer assembly process but also contributes to high-quality, compliant finishes in precast concrete structures.

The integration of electric box insert magnets in precast concrete design is revolutionizing the construction industry. These innovative magnets offer a seamless method for embedding electrical boxes within concrete walls and panels, reducing labor time and improving overall efficiency. According to a report by the Precast Concrete Institute, incorporating magnetic insert systems can lead to a 20-30% reduction in installation time, allowing contractors to maximize productivity and reduce project timelines.

One of the standout features of electric box insert magnets is their incredible flexibility. They can be easily repositioned during the casting process, ensuring precise placement without the hassle of traditional mounting methods. This adaptability not only enhances design versatility but also minimizes wastage, contributing to a more sustainable construction approach. A case study highlighted in the Journal of Construction Engineering and Management found that using magnetic inserts reduced material waste by over 15% compared to conventional methods.

**Tip:** When utilizing electric box insert magnets, ensure that you conduct thorough alignment checks during the initial setup phase. This can save time during installation and help avoid costly rework later. Additionally, consider continuous training for your team on the best practices for using these tools, as effective usage can substantially improve project outcomes.

| Advantage | Description | Impact on Design | Cost Efficiency |

|---|---|---|---|

| Increased Stability | Electric box insert magnets provide secure and stable placements within the precast concrete. | Allows for precise positioning of electrical boxes, reducing installation errors. | Minimizes wastage by reducing the need for adjustments and repairs. |

| Enhanced Efficiency | Streamlines installation processes by allowing quick placement of insertions. | Speeds up the precast concrete assembly process. | Reduces labor costs due to faster installations. |

| Flexibility in Design | Allows designers to create more complex structures with integrated electrical layouts. | Facilitates innovative architectural features by providing hidden electrical solutions. | Supports diverse design concepts without significant cost increase. |

| Durability | Magnets are designed to withstand the harsh conditions during precast concrete production. | Ensures that electrical components stay secure throughout the life of the structure. | Reduces long-term maintenance costs by preventing damage. |

| Improved Safety | Minimizes the risk of errors during installation by providing stable placements. | Encourages adherence to safety standards in electrical installations. | Potential cost savings by avoiding accidents or rework due to unsafe placements. |