The construction industry has been continually evolving, with innovations aimed at enhancing efficiency, safety, and cost-effectiveness. One such innovation is the use of 2100kg precast concrete magnets, which have become a vital component in modern construction practices. According to a report by Research and Markets, the precast concrete market is projected to grow at a CAGR of 5.5% from 2021 to 2026, highlighting the significant demand for precast solutions. The integration of advanced magnet systems not only streamlines the manufacturing process but also optimizes the construction workflow, leading to increased project turnaround times.

In a sector where speed and precision are paramount, the advantages provided by the 2100kg precast concrete magnets are substantial. These magnets facilitate the efficient handling and placement of heavy concrete forms, thereby minimizing labor costs and reducing the risk of accidents on-site. The National Institute for Occupational Safety and Health (NIOSH) has reported that appropriate safety measures and equipment can decrease construction-related injuries by over 30%. Thus, employing such innovative solutions becomes essential for contractors aiming to maintain safety and improve productivity.

Additionally, the operational efficiency gained from utilizing products manufactured at a reputable 2100kg precast concrete magnet factory can lead to a more sustainable construction process. With increasing pressure on the construction industry to reduce waste and improve sustainability, these magnets support lean manufacturing practices, enabling better resource utilization and reduced material waste. As the industry continues to prioritize both efficiency and sustainability, understanding the benefits of these precast concrete magnets will be crucial for stakeholders aiming to remain competitive in a rapidly changing environment.

The use of 2100kg precast concrete magnets offers significant benefits in enhancing structural stability within construction projects. These magnets are specifically designed to securely hold precast components in place during the curing process and assembly, leading to improved alignment and stability of the structures. By minimizing the risk of misalignment, they help ensure that the final product adheres to the design specifications, thus contributing to the overall integrity of the construction.

Moreover, the increased weight capacity of 2100kg allows for the handling of larger and heavier precast elements. This capability not only streamlines the construction process but also reinforces the stability of the structure being built. When precast components are firmly anchored, there is a reduced chance of shifting or settling over time, which can often lead to costly repairs and safety concerns. Ultimately, utilizing these robust magnets results in a safer, more reliable building environment that can withstand various loads and stresses encountered over its lifecycle.

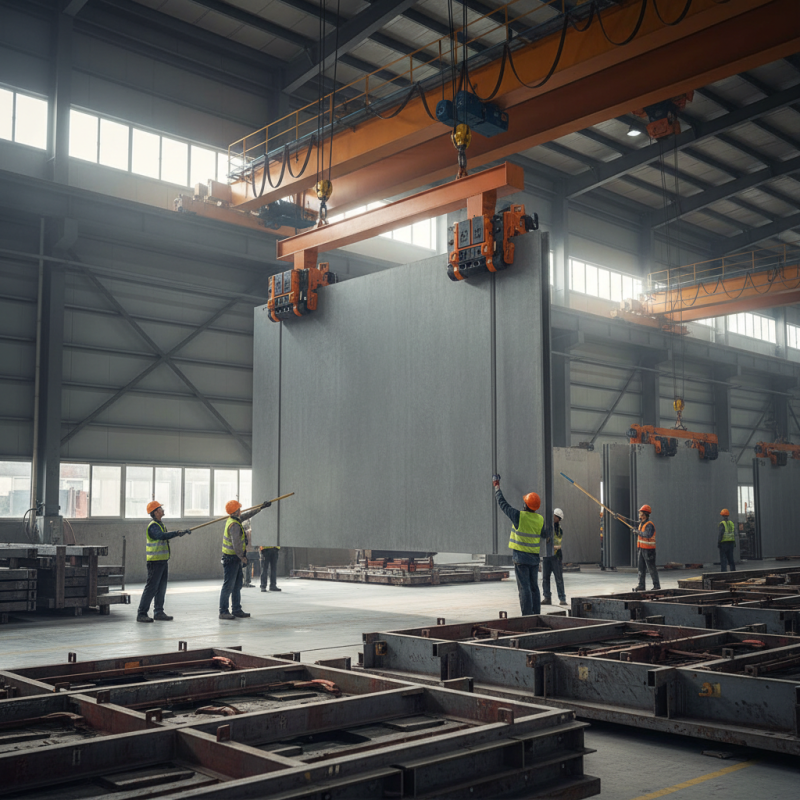

The use of 2100kg precast concrete magnets has transformed the installation processes of precast concrete components, bringing about remarkable improvements in efficiency. These magnets significantly streamline the handling and placement of heavy precast elements, reducing the time and manpower typically required for such operations. With their robust design, these magnets securely grip the concrete, allowing for precise positioning without the need for extensive rigging or additional support systems. This not only enhances safety on the construction site but also minimizes the potential for errors during installation.

Moreover, the adoption of precast concrete magnets eliminates the inefficiencies associated with traditional lifting methods. Workers can confidently maneuver and set precast pieces into place with reduced effort, leading to faster turnaround times on projects. The ease of use and quick release mechanisms of these magnets allow for rapid adjustments, which is particularly advantageous in complex building designs. Consequently, by improving operational workflows, precast concrete magnets play a crucial role in optimizing overall construction timelines, proving to be a valuable asset in modern construction practices.

The use of 2100kg precast concrete magnets in construction projects offers significant cost-effectiveness. These magnets streamline the labor-intensive processes typically associated with traditional concrete assembly, reducing both time and workforce requirements. By enabling quicker formwork adjustments and allowing for easier handling of heavy precast elements, they minimize downtime and accelerate the overall project timeline, ultimately lowering labor costs.

Moreover, utilizing 2100kg precast concrete magnets can lead to decreased waste and material costs. Since these magnets create an efficient connection between precast elements, they reduce the likelihood of errors and the need for corrective measures, which is often a financial drain in construction projects. Taking advantage of their strength and reliability means that fewer resources are required, and the long-term durability they provide ultimately saves money on repairs and maintenance.

Tips: When considering the integration of 2100kg precast concrete magnets, ensure that your team is well-trained on their use to maximize efficiency. Additionally, plan your layout strategically to achieve the best placement for these magnets, which can further enhance time savings and overall project cost-effectiveness. Lastly, keep an eye on market conditions for similar products, as advancements in technology could yield even more economical options in the future.

The versatility of 2100kg precast concrete magnets has made them a crucial tool in modern construction processes. These magnets are designed to securely hold precast concrete forms in place, facilitating a wide array of construction applications, from large-scale projects like bridges to the intricate designs of architectural facades. According to a report by the Precast/Prestressed Concrete Institute (PCI), the use of precast elements in construction can reduce on-site labor by up to 50% while significantly speeding up project timelines.

Furthermore, precast concrete magnets are not just limited to standard construction projects; they are adaptable to various environmental settings and construction techniques. Industry studies indicate that these magnets can bear substantial weights while maintaining their magnetic adhesion, thus ensuring the stability of forms during the pouring of concrete. This capability allows for complex geometrical shapes and customized designs, enabling architects and engineers to explore innovative solutions without compromising safety or efficiency. The ability to adjust the placement and usage of these magnets on-site speaks to their practicality and enhances workflow across multiple construction stages.

The adoption of precast concrete technologies, particularly the use of 2100kg precast concrete magnets in construction, presents significant environmental benefits that contribute to sustainable building practices. According to a report by the Portland Cement Association, precast concrete can reduce greenhouse gas emissions by up to 45% compared to traditional cast-in-place concrete methods. This reduction is largely attributed to the efficiency of the manufacturing process, which minimizes waste and utilizes materials more effectively.

One of the striking advantages of precast concrete is its ability to enhance energy efficiency during the construction phase and throughout the lifespan of the building. A study conducted by the National Ready Mixed Concrete Association highlights that structures made with precast concrete maintain energy savings of up to 20% over their lifetime due to their superior thermal mass properties. This means that buildings can regulate internal temperatures more effectively, reducing the reliance on heating and cooling systems, and consequently lowering energy consumption.

Moreover, the use of precast concrete technologies can also lead to significant reductions in water usage. The Concrete Plant Association reports that precast manufacturing processes typically consume 70% less water than traditional concrete pouring methods. As water scarcity becomes an increasingly pressing issue globally, implementing precast technologies in construction not only supports sustainability but also aligns with responsible resource management practices.