In the realm of precast concrete production, the efficiency and quality of manufacturing processes heavily rely on advanced tools and technology. Among these, the use of "Insert Magnets for Precast" has revolutionized the industry by significantly enhancing the positioning and securing of steel reinforcement elements within concrete molds. According to a report by MarketsandMarkets, the global precast concrete market is projected to reach $140.4 billion by 2026, growing at a CAGR of 5.8%. This highlights the increasing demand for efficient precast solutions, prompting the need for reliable insert magnets that ensure structural integrity and improve workflow.

Moreover, the choice of insert magnets can directly impact the productivity and cost-effectiveness of precast operations. Effective magnetic systems not only safeguard against misalignment during the curing process but also reduce the manpower required for adjustments, leading to time savings and enhanced safety on the production floor. As construction projects demand faster turnaround times, the adoption of high-performance insert magnets becomes critical. This article delves into the 10 best insert magnets for precast concrete production in 2023, evaluating their features, applications, and benefits, helping industry players make informed decisions in an evolving marketplace.

When selecting insert magnets for precast concrete applications, several best practices should be adhered to in order to ensure efficiency and reliability in production. One of the key considerations is the magnetic strength and type of material used in the inserts. According to the Precast/Prestressed Concrete Institute (PCI), using high-performance neodymium magnets can significantly enhance the holding strength, which is crucial in maintaining the alignment and stability of molds during the curing process.

Recent studies show that magnets with a pull force exceeding 200 pounds can reduce the potential for mold displacement by over 30%, thereby improving overall production quality.

Another important aspect is the compatibility of the insert magnets with various concrete mixes. Industry reports indicate that certain magnetic materials may corrode or degrade when exposed to high humidity or specific chemical compositions found in some concrete mixes. Therefore, it is essential to choose insert magnets that are coated with corrosion-resistant materials, such as nickel or epoxy.

Furthermore, understanding the production environment and the weight of the elements being produced will inform the selection of magnets that not only meet the strength requirements but also adhere well to the specific conditions of precast production sites. Prioritizing durability and performance can lead to optimized production cycles and lower long-term operational costs.

The selection of magnets for precast concrete production is critically influenced by the material strengths of the inserts. In 2023, advancements in material technology have led to the development of stronger and more durable magnetic inserts, essential for meeting the growing demands of the precast concrete industry. Innovations in neodymium magnets, for example, have enhanced their pull force while enabling them to maintain stability under varying temperatures and conditions. This ensures that the molds remain securely in place during the concrete setting process, minimizing the risk of defects in finished products.

Moreover, the integration of composite materials into magnet design has shown promising results in increasing resistance to corrosion and wear. Such durability is vital for the longevity of precast components, which often face harsh environmental conditions. As the industry moves toward more sustainable practices, selecting inserts that not only provide strength but also compatibility with eco-friendly production methods has become essential. In this context, a thorough analysis of these material strengths aids manufacturers in choosing the most effective magnet inserts for their specific needs, ensuring quality and reliability in precast concrete production.

| Insert Type | Material | Shear Strength (MPa) | Tensile Strength (MPa) | Weight (kg) | Cost (USD) |

|---|---|---|---|---|---|

| Standard Magnet Insert | Steel | 15.5 | 30.0 | 0.5 | 20 |

| Heavy Duty Magnet Insert | Aluminum | 20.0 | 35.0 | 0.7 | 25 |

| Lightweight Magnet Insert | Plastic | 10.0 | 20.0 | 0.3 | 15 |

| Corrosion Resistant Insert | Stainless Steel | 18.0 | 32.0 | 0.6 | 30 |

| Eco-Friendly Magnet Insert | Biodegradable Plastic | 12.5 | 22.0 | 0.4 | 18 |

When considering the efficiency of inserts magnets in precast concrete production, a comparative analysis of traditional and modern options reveals significant differences in performance and application. Traditional inserts often rely on metal cores that may rust and lose magnetic efficiency over time, which can compromise the quality and durability of precast elements. In contrast, modern insert magnets utilize advanced materials such as high-strength neodymium, offering enhanced adhesion, stability, and resistance to corrosion, leading to a more reliable production environment.

**Tips:** When selecting magnets for precast production, always assess the specific environmental factors they will be exposed to. For example, if the production area is prone to moisture, opt for magnets with a protective coating to prevent degradation. Furthermore, consider the size and shape of your precast components, as the right magnet configuration can significantly streamline assembly processes and reduce labor costs.

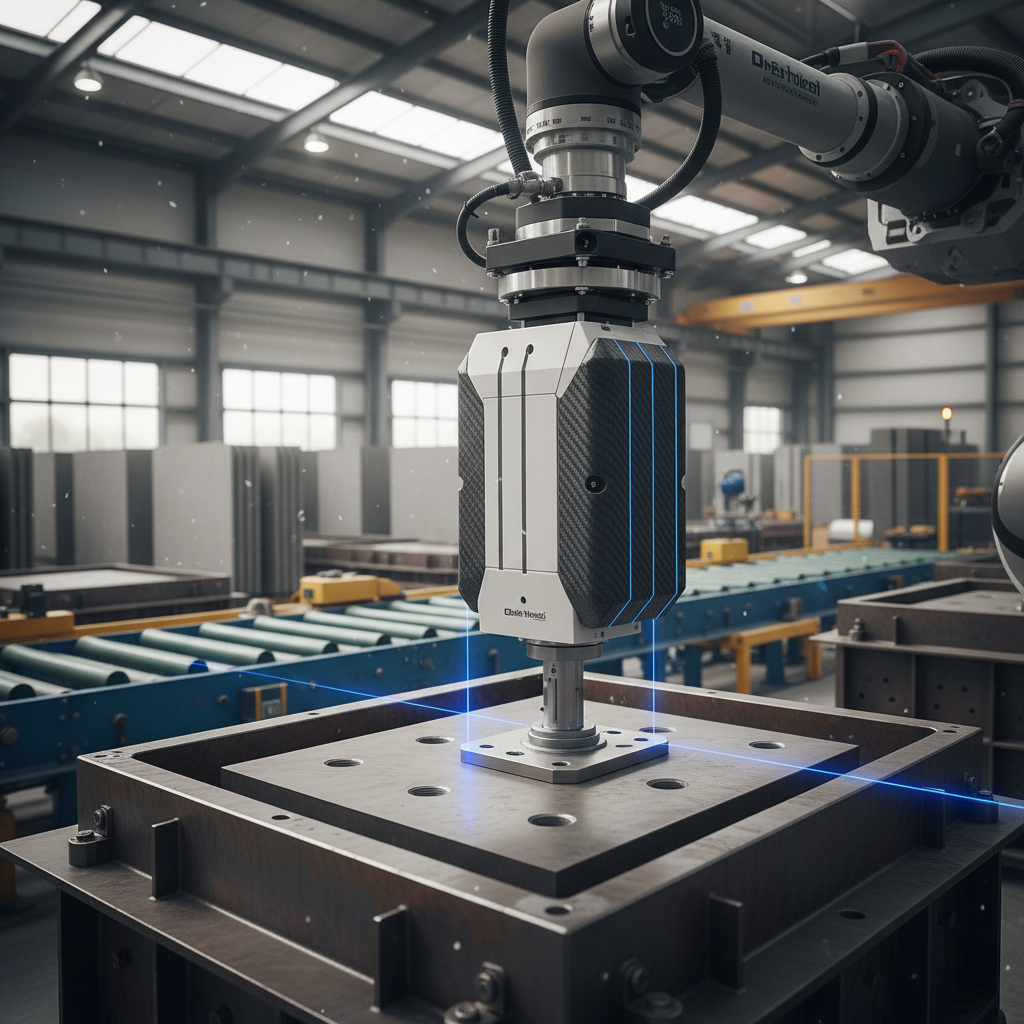

The evolving technology in magnets also presents opportunities for improved automation in precast concrete production. Manufacturers are increasingly integrating magnetic systems with automated machinery, resulting in faster and more precise placements of inserts. Using modern magnets not only enhances efficiency but also expands design potential, allowing for more intricate and innovative concrete shapes that meet modern construction demands.

The environmental impact and sustainability of insert magnets in concrete manufacturing have garnered increasing attention, especially as the construction industry aims to align with circular economy principles. According to the International Materials Recycling Association, the need for recycled materials is projected to rise significantly, which directly influences the demand for innovative solutions in precast concrete production. One promising development involves integrating rare mineral by-products from mining waste into concrete mix designs, enhancing both strength and sustainability. Recent research from Flinders University indicates that these materials can not only reduce the carbon footprint of concrete but also contribute to the industry’s shift towards a more circular model.

Moreover, analyzing the trends in the cement industry, it's noteworthy that the market size in Japan is anticipated to reach 61.4 million tons by 2033, highlighting the expansion of both public and private construction initiatives. As the sector grows, the implementation of inserts using sustainable magnets can significantly improve production efficiency, aligning with the broader goal of reducing environmental impacts. This shift indicates a profound potential for integrating technology and sustainability, with reports suggesting that companies focusing on circular value chains can better meet the growing demands of the construction market.

Emerging technologies in insert magnets are revolutionizing the precast concrete industry by enhancing production efficiency and quality. These innovations focus on sophisticated magnet designs that improve the precision and speed of placing inserts within molds. For instance, advancements in composite materials and magnetic technology have led to lighter yet stronger magnets that provide more reliable attachment to various substrates. This not only reduces setup time but also minimizes the risk of displacement during the pouring process.

Moreover, the integration of smart technologies, such as IoT-enabled sensors, is shaping the future of inserts magnets in precast concrete production. These sensors can monitor the positioning and integrity of the magnets in real-time, providing valuable data for quality control and operational efficiency. This level of connectivity allows manufacturers to optimize their production processes, ensuring that every component meets stringent industry standards while minimizing waste and downtime. As the industry continues to embrace these emerging technologies, the potential for innovation in precast concrete production remains vast.