In the rapidly evolving world of construction technology, the Shuttering Magnet System for Precast Formwork is gaining recognition for its innovative approach to enhancing efficiency and quality in precast concrete applications. As we look towards 2025, industry experts emphasize the importance of modern techniques in maintaining competitiveness. Renowned precast concrete specialist Dr. Emily Harper states, "The Shuttering Magnet System for Precast Formwork not only streamlines the assembly process but also provides unmatched precision, which is crucial for meeting today's rigorous standards."

In the rapidly evolving world of construction technology, the Shuttering Magnet System for Precast Formwork is gaining recognition for its innovative approach to enhancing efficiency and quality in precast concrete applications. As we look towards 2025, industry experts emphasize the importance of modern techniques in maintaining competitiveness. Renowned precast concrete specialist Dr. Emily Harper states, "The Shuttering Magnet System for Precast Formwork not only streamlines the assembly process but also provides unmatched precision, which is crucial for meeting today's rigorous standards."

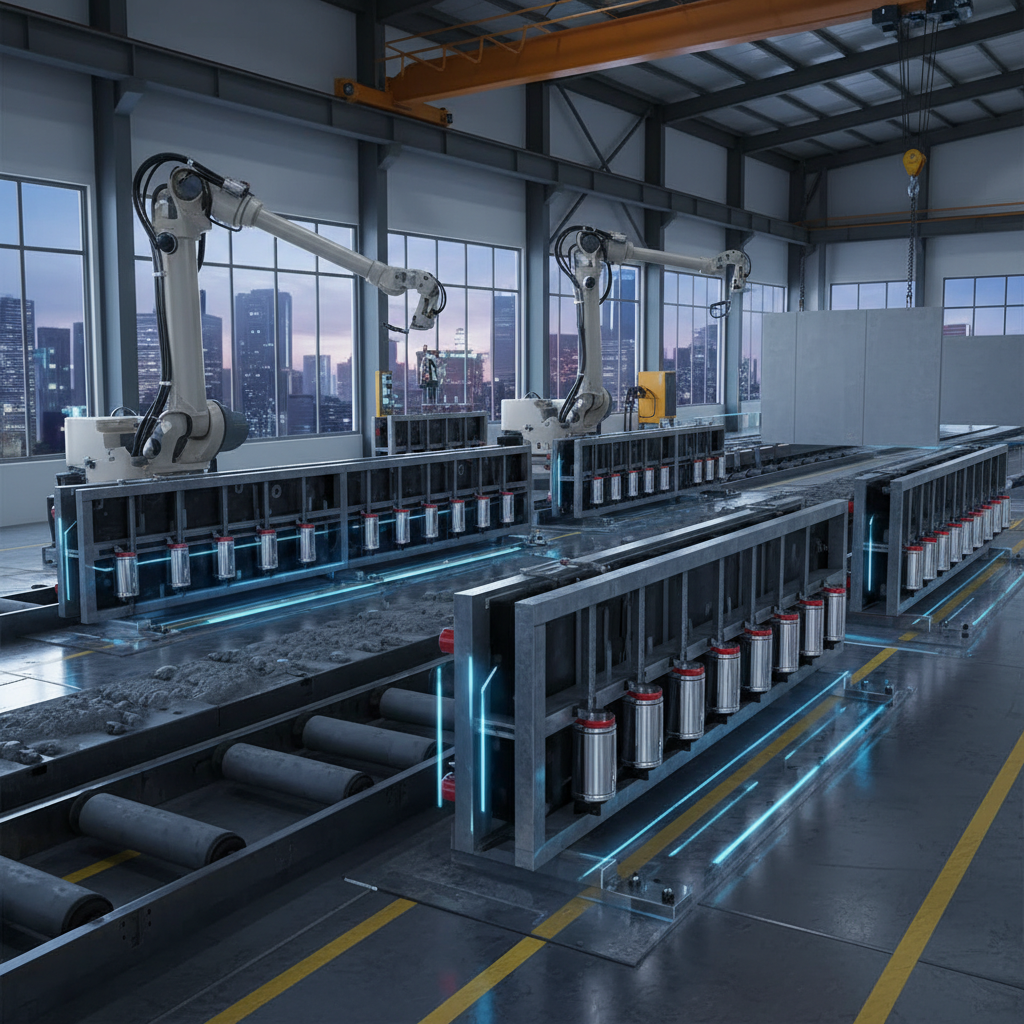

This groundbreaking system allows for quicker setup times and increased flexibility on site, addressing the evolving needs of the construction sector. By utilizing magnetic technology, contractors can achieve a level of adaptability unheard of in traditional formwork systems. As we explore the top ten strategies to effectively implement this technology in the upcoming year, it becomes clear that understanding its benefits and best practices will be essential for maximizing its potential. In 2025, the construction landscape will be transformed by solutions like the Shuttering Magnet System for Precast Formwork, leading to greater productivity and outstanding results in concrete construction.

The construction industry is evolving rapidly, and understanding the fundamentals of shuttering magnet systems is crucial for maximizing efficiency in precast formwork. Shuttering magnets offer a modular and flexible formwork solution that enables faster construction times and improved safety on site. According to industry reports, adopting advanced formwork systems like shuttering magnets can reduce construction cycle times by up to 30%, significantly impacting overall project timelines. These systems allow for precise alignment and secure fastening of formwork panels, which is essential for achieving high-quality precast concrete components.

Moreover, the integration of shuttering magnet systems in precast construction aligns with the industry's push towards innovation. A recent survey indicated that approximately 70% of project managers recognize the necessity for modernizing construction techniques to enhance productivity and meet increasing demands. By utilizing shuttering magnets, teams can minimize labor costs and the potential for human error, contributing to a more reliable and cost-effective construction process. As we approach 2025, the embrace of these innovative solutions is imperative for construction firms aiming to leverage the full potential of their operations.

In modern construction, the integration of shuttering magnet systems offers significant advantages that streamline the precast formwork process. By utilizing these innovative systems, builders can achieve greater efficiency in the assembly and dismantling of formwork, thereby minimizing labor costs and reducing project timelines. The magnetic technology ensures that forms are securely held in place, allowing for precise alignment and consistency in the casting of concrete structures, which contributes to improved overall quality and durability.

Moreover, as the global construction automation market is projected to grow from $87.85 billion in 2025 to $154.74 billion by 2032, employing such advanced technologies becomes essential for companies aiming to stay competitive. The adoption of shuttering magnet systems not only enhances operational efficiency but also supports sustainable practices by reducing waste and optimizing resource use. This synergy between technology and construction methodologies positions these systems as indispensable tools for achieving net-zero energy buildings in the future.

In 2025, the precast concrete industry continues to evolve with cutting-edge innovations in shuttering magnet technology. These advancements are designed to enhance efficiency, reduce labor costs, and improve the overall quality of precast elements. With powerful magnetic systems, the alignment and stabilization of formwork become effortless, allowing for faster production cycles. Engineers and contractors can now expect a smoother workflow and superior end products, thanks to these innovative solutions.

Tips for Using Shuttering Magnet Systems Effectively: When employing shuttering magnets, ensure to clean the surfaces thoroughly. Any debris can affect the adhesion and alignment of the forms, leading to imperfections in the final product. Additionally, regularly inspecting magnets for wear and tear will prevent unexpected failures during the casting process.

Furthermore, integrating these magnets with advanced digital monitoring systems can optimize their performance. By tracking the load distribution and real-time adjustments during the setting process, teams can achieve greater precision and minimize resource waste, setting a new standard in precast formwork applications. Leveraging these technologies not only enhances productivity but also contributes to more sustainable practices within the construction industry.

The implementation of shuttering magnet systems in precast formwork has revolutionized the construction process, particularly in 2025. These systems not only enhance efficiency but also ensure precision in building structures. To effectively use shuttering magnets on job sites, it's crucial to follow best practices that enhance productivity and safety.

One essential tip for implementing shuttering magnet systems is to conduct thorough training for your crew. Ensure that all team members understand the operational procedures and safety protocols associated with the systems. This knowledge can significantly reduce the risk of accidents and improve the overall workflow. Regular training sessions can also keep the team updated on any new technologies or improvements in the shuttering magnet designs.

Additionally, maintaining a clean and organized job site is vital for the effective use of shuttering magnets. Create designated areas for tools and materials to prevent confusion and potential hazards. This practice not only streams the workflow but also allows easier access to the shuttering magnets when adjustments or repairs are needed. An orderly site promotes teamwork and enhances the overall effectiveness of the construction process.

In 2025, the use of shuttering magnet systems for precast formwork is poised to undergo significant transformation, primarily driven by two key factors: automation and sustainability. According to a report by MarketsandMarkets, the market for automation in construction is expected to reach $10 billion by 2025, a trend that emphasizes the growing demand for more efficient and innovative solutions. Shuttering magnets, which allow for quick and precise formwork setups, are increasingly integrated with automated technologies that streamline the manufacturing process, reducing labor costs and time. This shift not only enhances productivity but also improves safety on construction sites, where manual handling can lead to accidents.

Sustainability is another critical aspect shaping the future of shuttering magnet usage. The World Green Building Council reports that the construction industry is responsible for approximately 39% of global carbon emissions. As a result, manufacturers are compelled to adopt eco-friendly practices and materials in their lead times. Shuttering magnets, being reusable and requiring less concrete for structural integrity, contribute significantly to minimizing waste. Moreover, companies that implement sustainable practices, such as energy-efficient magnet systems, often see a 20% decrease in overall project costs, making these innovations not only environmentally responsible but also economically advantageous.