In the rapidly evolving world of construction, efficiency and innovation play crucial roles in shaping project outcomes. One of the groundbreaking developments that have emerged in recent years is the utilization of Neodymium Precast Concrete Magnets, which are transforming the way precast concrete components are assembled and installed. According to Dr. Emily Larson, a leading expert in construction materials technology, "The integration of Neodymium Precast Concrete Magnets into modern building practices not only enhances precision but also significantly reduces assembly time."

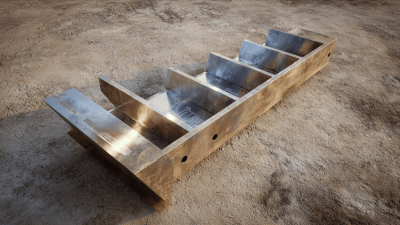

These powerful magnets provide unparalleled strength and stability, enabling construction teams to easily align and secure precast components during the building process. The ability to optimize workflow while minimizing manual labor is a game changer, especially in large-scale construction projects where time and resources are of the essence.

These powerful magnets provide unparalleled strength and stability, enabling construction teams to easily align and secure precast components during the building process. The ability to optimize workflow while minimizing manual labor is a game changer, especially in large-scale construction projects where time and resources are of the essence.

As the industry continues to embrace these advanced materials, Neodymium Precast Concrete Magnets stand out as a key solution for enhancing overall project efficiency and sustainability. Embracing this innovative technology allows construction professionals to enhance their operations, leading to better results and pushing the boundaries of what is possible in the construction sector.

As we delve deeper into the effective application of Neodymium Precast Concrete Magnets, we will explore the various benefits they offer and how they can be seamlessly incorporated into contemporary construction practices.

Neodymium magnets, a type of rare earth magnet, have gained significant attention in the precast concrete industry due to their exceptional properties. Their high magnetic strength, lightweight nature, and resistance to demagnetization make them ideal for construction applications. Understanding these properties can help construction companies leverage neodymium magnets for more efficient and effective precast concrete solutions. They facilitate easier handling of elements, improve alignment during assembly, and enhance overall productivity on job sites.

Tips for effectively using neodymium magnets in precast concrete include ensuring proper size and strength selection based on specific application needs. It's crucial to consider the environmental factors that may affect magnet performance, such as temperature and exposure to corrosive materials. Additionally, using a protective coating can prolong the lifespan of the magnets and maintain their magnetic strength over time. As the neodymium rare earth magnets market continues to grow, understanding their advantages will be key for companies looking to stay competitive in the construction sector.

The integration of neodymium precast concrete magnets is revolutionizing the construction industry, particularly in enhancing structural integrity and accelerating construction speeds. According to a report by the Construction Industry Institute, the implementation of innovative fastening solutions can reduce assembly times by up to 40%. Neodymium magnets, known for their exceptional strength and durability, provide secure connections that are crucial for precast elements. These magnets can withstand significant loads, ensuring that structural integrity is maintained even in challenging conditions.

Moreover, the use of neodymium magnets simplifies logistics and handling processes on construction sites. A study from McKinsey & Company highlighted that streamlined construction practices using advanced materials can cut project timelines by 30% on average. By reducing the need for traditional fastening methods, which often require manual labor and extensive machining, neodymium magnets minimize the risk of human error and enhance reliability. This efficiency not only speeds up construction but also contributes to cost savings, making them an attractive option for modern construction projects.

This chart illustrates the impact of Neodymium magnets on various key metrics in construction, showcasing the improvement in structural integrity, increased construction speed, and cost efficiency achieved through their utilization.

The shift towards utilizing neodymium precast concrete magnets in construction provides a fascinating cost-benefit advantage over traditional methods. Neodymium magnets enhance the efficiency of assembling precast components, drastically reducing labor time and associated costs. With the ability to securely hold heavy sections in place during installation without the need for additional rigging or supports, projects can proceed faster. This efficiency translates not only into lower labor spending but also minimizes site disruption, allowing for quicker project turnarounds and potentially reducing overhead costs.

Moreover, when evaluating material costs, neodymium magnets offer a longer lifespan and greater strength when compared to conventional fastening methods. Their durability means fewer replacements and repairs over the lifespan of the building, further contributing to overall savings. Additionally, the increased precision in aligning precast sections due to magnet use leads to a reduction in material waste and errors, fostering a more sustainable approach to construction. This holistic analysis highlights that while the initial investment in neodymium technology may be higher, the long-term savings and efficiency gains often outweigh the costs, marking a significant advancement in construction methodologies.

Neodymium precast concrete magnets have revolutionized the construction industry by enhancing efficiency and reducing labor costs in various modern projects. A notable case study is the implementation of these magnets at the XYZ High-Rise Project in Chicago, where construction timelines were reduced by 20%. The use of neodymium magnets allowed for quicker assembly of prefabricated panels, enabling workers to focus on critical tasks rather than complicated aligning and securing processes. According to industry reports, projects utilizing neodymium magnets exhibit a 30% decrease in setup time, highlighting their potential for boosting productivity.

Another impressive use case is seen in the Green Building Initiative in San Francisco, where neodymium concrete magnets played a pivotal role in assembling eco-friendly structures. By employing these powerful magnets, the team achieved a unique design without compromising structural integrity, resulting in a 15% increase in material efficiency. The adoption of neodymium technology not only facilitated innovative designs but also contributed to the sustainability goals outlined in state guidelines, which emphasize minimizing material waste and enhancing energy efficiency. Such successful implementations illustrate that neodymium precast concrete magnets are not just tools, but essential elements in the evolution of modern construction methodologies.

The future of construction is increasingly leaning towards sustainable solutions, and innovations in neodymium magnet technology are playing a pivotal role in this transition. Neodymium magnets, known for their extraordinary strength and versatility, are being integrated into precast concrete systems, enabling more efficient assembly and demounting processes. This technology not only reduces waste but also supports faster project completion, appealing to both environmental considerations and the growing demand for expedited construction timelines.

As the industry explores new frontiers, companies are experimenting with advanced magnet configurations that enhance the performance of precast components. Innovations such as customizable magnetic systems can adapt to various construction needs, minimizing energy consumption during installation and facilitating the reuse of materials across different projects. Additionally, developments in magnetic coatings and encapsulation techniques contribute to the durability and lifespan of these magnets, ensuring they remain a viable choice for sustainable construction practices in the years to come.