The construction industry is increasingly embracing innovative technologies to enhance efficiency and sustainability, with Neodymium Precast Concrete Magnets emerging as a key player in this transformation. According to a recent report by Smith and Associates, the global precast concrete market is projected to reach $140 billion by 2025, with a significant portion attributed to advancements in magnetic systems that simplify assembly and reduce labor costs. Neodymium magnets, known for their exceptional strength-to-weight ratio, are revolutionizing the way precast elements are secured during construction.

This blog will explore the best examples of Neodymium Precast Concrete Magnets in various construction projects, highlighting their impact on improving workflow, safety, and project timelines, while also emphasizing the importance of adherence to industry import and export certifications that ensure quality and compliance.

Neodymium magnets have revolutionized the way precast concrete is utilized in construction. These powerful magnets are being integrated into various stages of the precast process, from facilitating easier transportation of heavy panels to enhancing assembly efficiency at the construction site. Their superior strength allows for a secure hold on forms, reducing the need for traditional fastening methods that can be cumbersome and time-consuming.

One innovative application involves using neodymium magnets for aligning and temporarily securing precast elements during installation. This method not only speeds up the assembly process but also minimizes the risk of misalignment, ensuring a seamless fit and improving overall structural integrity. Additionally, magnets can be used to create customizable attachments for electrical and plumbing installations, providing flexibility and precision that conventional methods cannot achieve.

Tips: When incorporating neodymium magnets into your precast concrete projects, consider their weight capacity to ensure safety and effectiveness. It’s also essential to test the magnets under various conditions to assess their performance in real-world scenarios. Finally, explore pairing magnets with advanced design software to create optimized layouts that enhance both function and aesthetics in your construction projects.

As the construction industry continues to evolve, innovative applications of neodymium magnets have emerged as game-changers. These powerful magnets offer several benefits that enhance building projects, particularly in precast concrete elements. Their exceptional strength-to-weight ratio allows for the efficient assembly of modules, improving construction speed and reducing labor costs. Moreover, neodymium's corrosion resistance ensures durability, making these magnets suitable for both indoor and outdoor applications.

One critical advantage of incorporating neodymium magnets in construction is their ability to improve structural integrity. By strategically placing these magnets in connections, builders can achieve stronger joint adhesion without the need for traditional fasteners that may compromise the aesthetics of a structure.

**Tips for Using Neodymium Magnets in Construction**: First, always evaluate the strength and size of the magnets needed for your project, as these factors can significantly impact performance. Second, consider the environmental conditions where the magnets will be used; selecting coated options can help mitigate corrosion in harsher environments. Lastly, ensure all safety precautions are observed when handling these strong magnets to prevent accidental injuries.

Neodymium magnets are revolutionizing construction techniques by significantly enhancing structural integrity through innovative applications. Recent industry reports indicate that the use of neodymium magnets in precast concrete elements can improve load-bearing capacities by up to 30%. This is primarily due to the magnets' exceptional strength-to-weight ratio, allowing for more efficient designs without compromising durability. In precast applications, these magnets facilitate the precise alignment of elements during assembly, ensuring seamless connections that contribute to overall stability.

Moreover, the integration of neodymium magnets in construction provides a level of flexibility previously unheard of in traditional methods. A study conducted by the International Journal of Structural Engineering demonstrated that structures utilizing magnetic joining methods reported a reduction in assembly time by nearly 25%, leading to significant cost savings and increased productivity on job sites. Such advancements not only streamline construction processes but also contribute to sustainable practices by minimizing waste and maximizing resource efficiency.

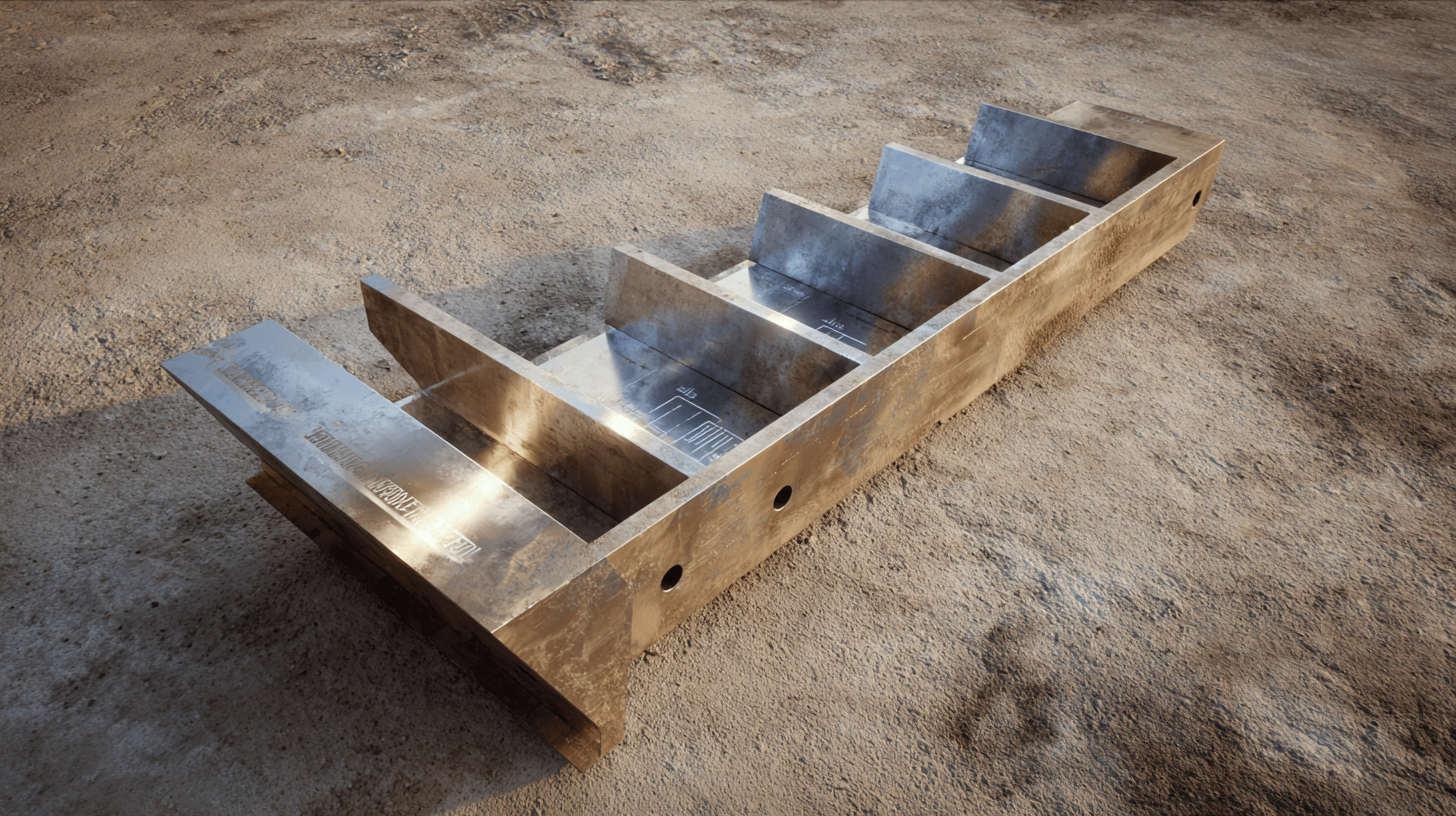

In modern construction, neodymium magnets are increasingly becoming indispensable tools, demonstrating their versatility and strength in various applications. One notable example is their use in precast concrete formwork. By embedding neodymium magnets within the forms, contractors can ensure accurate alignment and secure connections between different sections of concrete. This technique not only saves time during the assembly process but also enhances the integrity of the construction, as the magnets provide powerful holding forces that eliminate the need for additional fasteners.

Another innovative application of neodymium magnets is in modular building designs, where they facilitate the easy assembly and disassembly of components. These magnets enable sections of buildings to be linked and released effortlessly, allowing for flexibility in design and quick reconfiguration of spaces. This simplicity is particularly beneficial in urban environments, where projects often require rapid deployment and adaptability to changing needs. Through these real-world examples, it is evident that neodymium magnets are revolutionizing traditional construction methods, paving the way for a more efficient and dynamic building industry.

This chart illustrates the various innovative applications of neodymium magnets in construction, highlighting their usage frequency in different project types. Magnetic lifting is the most common application, followed by reinforcement bonding and formwork systems. Such applications demonstrate the versatility and efficiency of neodymium magnets in enhancing modern construction practices.

As the construction industry increasingly focuses on sustainability, the role of neodymium magnets in precast concrete applications is evolving significantly. According to a report by Research and Markets, the global precast concrete market is projected to grow to $192.9 billion by 2027, with sustainable practices driving much of that growth. Neodymium magnets, known for their exceptional strength-to-weight ratio, are being harnessed to enhance modular construction methods, enabling quicker assembly while minimizing waste.

Innovative applications of neodymium magnets are gaining traction in the realm of sustainable building practices. For instance, their incorporation into precast panels allows for precise positioning and alignment during installation, thereby reducing reliance on heavy equipment and lowering carbon footprints. A study from the Journal of Cleaner Production highlighted that implementing efficient modular construction techniques, facilitated by neodymium magnets, can lead to a reduction of up to 30% in resource consumption compared to traditional building methods. As the construction sector continually seeks to improve efficiency and sustainability, the adoption of neodymium magnets is set to play a pivotal role in the future of eco-friendly building practices.

| Application | Description | Benefits | Future Trends |

|---|---|---|---|

| Magnetic Formwork Systems | Use of neodymium magnets to hold formwork in place without traditional fastening methods. | Increased efficiency and reduced assembly time. | Integration with smart technology for automated construction. |

| Magnetic Anchoring | Using neodymium magnets to anchor structures securely to their bases. | Enhanced structural integrity and stability. | Growth in use for modular and temporary structures. |

| Energy-Efficient Magnetic Lifts | Using magnets to lift and move heavy concrete pieces during construction. | Reduced labor costs and enhanced safety. | Potential for greater automation and remote control technologies. |

| Magnetic Barrier Systems | Installation of barriers using neodymium magnets for easy repositioning. | Flexibility in design and adaptability to changes. | Increased prevalence in sustainable buildings for dynamic space management. |