In today's fast-paced construction industry, the demand for efficiency and quality has never been higher, particularly in precast concrete projects. One of the most innovative advancements that has emerged is the use of Shuttering Magnets for precast production. These powerful tools not only streamline the manufacturing process by providing precise formwork and alignment but also significantly reduce labor costs and time.

However, the benefits do not end with their initial application. Understanding the advantages of after-sales services and maintenance costs associated with Shuttering Magnets is crucial for maximizing their value in any project. In this blog, we will explore innovative applications of these magnets, discussing their role in enhancing productivity, ease of use, and long-term investment savings through effective maintenance strategies. Join us as we delve into how to effectively utilize Shuttering Magnets in modern precast concrete projects while ensuring lasting reliability and cost-efficiency.

As the precast concrete industry evolves, the adoption of shuttering magnets has significantly transformed project efficiency and design flexibility. According to a report by the Precast/Prestressed Concrete Institute (PCI), the utilization of innovative shuttering magnet technology has led to a 30% reduction in formwork setup time, allowing for faster project turnaround. These magnets, designed for rapid and secure connections, are becoming essential in modern precast applications, enabling more complex architectural designs while maintaining structural integrity.

Emerging trends in shuttering magnet technology reveal advancements in magnet strength and durability, enhancing the capability to withstand harsher construction environments. A recent market analysis by Research and Markets notes that the global shuttering magnet market is poised to grow by 12% annually, driven by increasing demand for sustainable construction solutions. This growth underscores the importance of integrating smart technologies, such as automated positioning systems and real-time monitoring, into magnet designs, fostering safer and more efficient workflows in precast concrete projects.

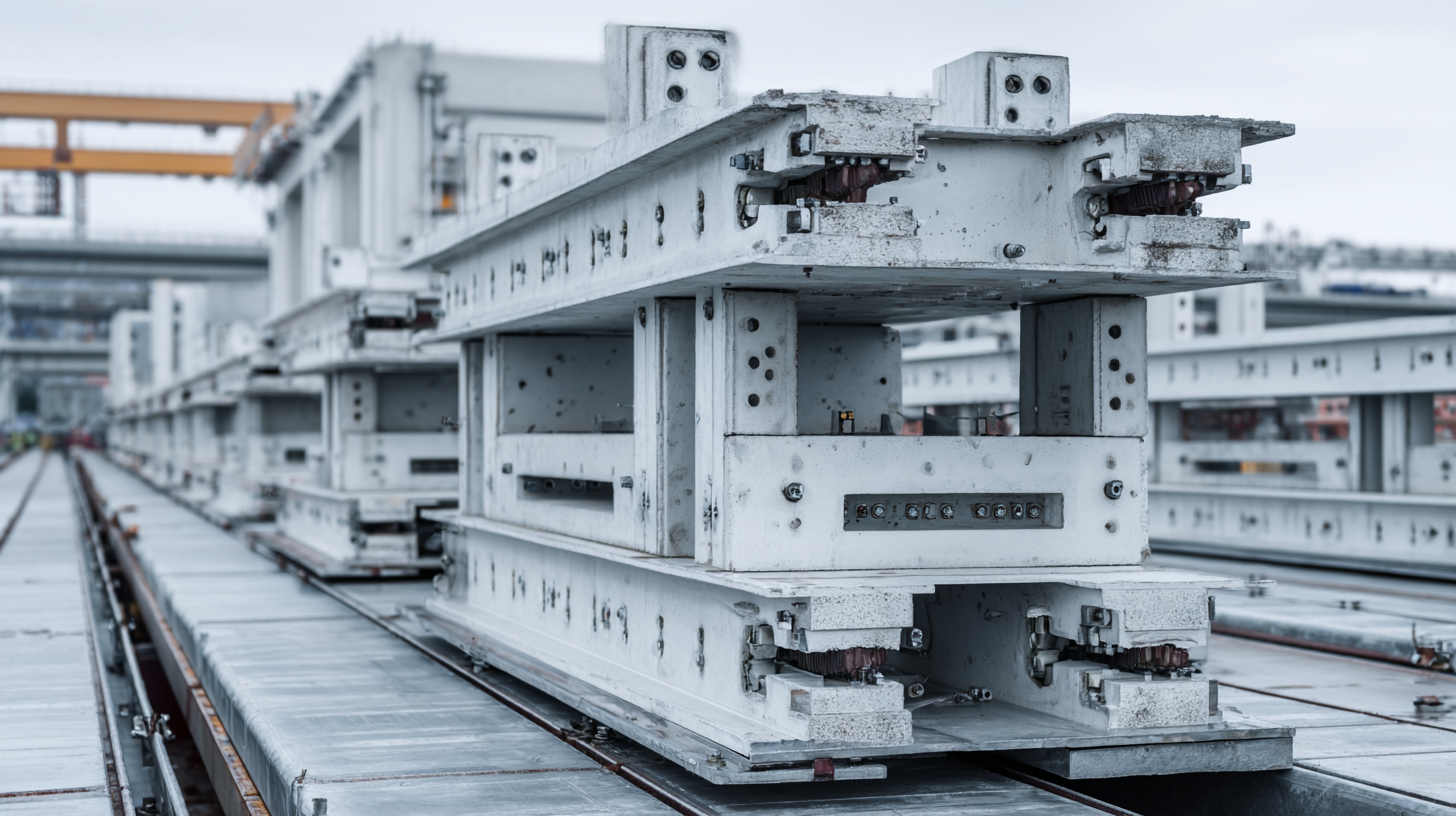

Shuttering magnets have revolutionized the precast concrete industry by offering numerous advantages that enhance construction efficiency and precision. One of the primary benefits of using shuttering magnets is their ability to provide robust, secure formwork without the need for cumbersome traditional equipment. This results in faster setup times and a safer working environment, as workers can focus on the pouring and finishing processes instead of wrestling with heavy frames.

Shuttering magnets have revolutionized the precast concrete industry by offering numerous advantages that enhance construction efficiency and precision. One of the primary benefits of using shuttering magnets is their ability to provide robust, secure formwork without the need for cumbersome traditional equipment. This results in faster setup times and a safer working environment, as workers can focus on the pouring and finishing processes instead of wrestling with heavy frames.

Tip: When implementing shuttering magnets, ensure that they are placed strategically to maintain optimal alignment and stability throughout the curing process. This helps prevent any deviations that could affect the structural integrity of the concrete.

Another significant advantage of shuttering magnets is their versatility in various applications. They can be easily adjusted or repositioned, allowing for the creation of complex shapes and designs without the hassle of reworking formwork. This flexibility not only saves time but also reduces material costs, making projects more economically feasible.

Tip: Consider using a combination of different size magnets for varying thicknesses of formwork. This approach ensures that you have the right support for every project requirement, optimizing the use of materials while maintaining quality.

Implementing shuttering magnets in your precast concrete projects can enhance both efficiency and precision in construction. To begin with, assess your project requirements and identify where shuttering magnets can replace traditional clamps or ties. This can lead to significant reductions in labor time and costs. Ensure that your team is familiar with the specific handling and safety protocols associated with these magnets, as their operation involves careful adherence to guidelines to prevent accidents.

Next, create a checklist that includes essential steps such as measuring the dimensions of the forms accurately, selecting the appropriate size and strength of the magnets for your panels, and planning the layout of magnets on the formwork. It’s vital to prioritize proper alignment to ensure that the concrete achieves the desired finish without any discrepancies. Regularly inspect the magnets for wear and ensure that they are cleaned to maintain their effectiveness. Implementing these structured steps will facilitate a smooth workflow and lead to successful outcomes in your precast concrete projects.

Shuttering magnets have long been a staple in precast concrete projects, primarily known for their role in securing formwork during the casting process. However, innovative applications of these powerful magnets are extending their utility far beyond standard uses. According to a report by Grand View Research, the global precast concrete market is expected to reach USD 150.56 billion by 2028, driven significantly by advancements in manufacturing techniques, including the adoption of shuttering magnets.

One remarkable application of shuttering magnets is in the construction of complex architectural designs. Their ability to hold formwork in place with precision allows architects to push boundaries, creating intricate shapes and structures that were previously unfeasible. Additionally, data from the World Economic Forum highlights that using precast elements can improve construction efficiency by up to 30%, with shuttering magnets playing a crucial role in minimizing the labor involved in traditional formwork systems.

Moreover, the versatility of shuttering magnets is now being explored in sustainable construction practices. By facilitating the reuse of formwork across multiple projects, they contribute to reducing material waste. The World Business Council for Sustainable Development reported that up to 40% of energy consumption in the construction sector can be attributed to material production. Hence, integrating shuttering magnets to enhance formwork reusability can lead to significant reductions in environmental footprint, aligning with contemporary goals for sustainable development in the construction industry.

The integration of smart technology into shuttering systems is poised to revolutionize the precast concrete industry. Smart sensors and IoT (Internet of Things) devices are being embedded into shuttering magnets, allowing for real-time monitoring of structural integrity and environmental conditions. This advancement can significantly enhance the production process by providing immediate feedback on the curing progress and detecting any potential issues before they become costly problems. The use of data analytics can optimize the placement and alignment of shuttering elements, ensuring higher precision and reducing waste.

Moreover, future developments in artificial intelligence (AI) could enable predictive maintenance of shuttering systems. By analyzing historical performance data, AI algorithms could forecast when equipment requires servicing, thus minimizing downtime and maximizing efficiency. This transformation from traditional methods to smart, data-driven approaches will not only improve the quality of precast elements but also streamline operations, making projects more cost-effective and environmentally sustainable. As technology continues to advance, the role of smart systems in shuttering development will undoubtedly expand, paving the way for innovative construction techniques and enhanced project outcomes.

| Project Type | Application of Shuttering Magnets | Smart Technology Integration | Benefits |

|---|---|---|---|

| Multi-Story Buildings | Quick installation and repositioning of formwork | Real-time monitoring of formwork alignment | Reduced labor costs and time savings |

| Bridges | Secure fastening of precast sections | Automated stress testing of forms | Increased structural integrity and safety |

| Highway Barriers | Flexible form configurations | Integration with CAD systems for design precision | Enhanced design accuracy and customization |

| Residential Sectors | Efficient casting of wall panels | Smart sensors for temperature and humidity | Improved curing process and durability |

| Industrial Structures | Rapid setup for large-scale molds | Data analytics for process optimization | Increased production efficiency and cost reduction |