In the world of precast concrete, efficiency is key. Insert magnets for precast applications offer innovative solutions. They provide reliable placement of reinforcement and fixtures. This helps in achieving high precision during the production process.

Using insert magnets improves time management. Workers can quickly position and secure components. The enhancement in workflow reduces delays in production. Many contractors appreciate this advantage. However, some still question the reliability of these tools.

There’s also the consideration of cost. While insert magnets are a smart investment, initial expenses can be high. Balancing quality with affordability is crucial. Ultimately, evaluating the benefits of insert magnets for precast is essential. With mindful consideration, these tools can greatly impact concrete project outcomes.

Insert magnets are becoming increasingly popular in precast concrete applications. These innovative tools work by securely holding forms in place during the concrete pouring process. They help ensure that each piece is manufactured with precision. The use of insert magnets simplifies the setup, reducing both time and effort on job sites.

In many cases, it can be challenging to align forms perfectly. Insert magnets address this issue. They offer a strong magnetic pull that keeps everything aligned. This means less risk of errors or misalignment. Workers often notice an improvement in overall efficiency. Additionally, magnets can be reused, contributing to cost-effectiveness in the long run.

However, reliance on insert magnets is not without flaws. Sometimes, they may not hold as strongly as expected, especially in humid conditions. It’s essential to consider environmental factors. Regular inspections can prevent mishaps. Quality control should always be a priority. In this evolving industry, every innovation brings new lessons to ponder.

Using insert magnets in precast concrete applications brings numerous advantages that can enhance production efficiency. These magnets help to streamline the process of setting reinforcement in molds. By holding steel bars in position, they reduce the need for manual adjustments. This can lead to quicker turnaround times for each mold cycle.

Workers appreciate the precision that insert magnets provide. The accuracy also minimizes errors during pouring. However, it's vital to ensure proper placement of the magnets to avoid complications later in production. If the magnets are not aligned correctly, it could lead to structural weaknesses. This is a learning point for many users.

Another benefit is the reduction in labor costs. With less manual handling, teams can focus on other critical areas. But it's essential to monitor how effectively the magnets are used in practice. Misalignment or incorrect magnet strength can lead to costly issues that require rework. Thus, while insert magnets offer great potential, careful oversight is necessary to maximize their advantages.

Insert magnets offer significant benefits in precast concrete applications, particularly in enhancing structural integrity. These magnets can hold elements in alignment during the curing process. This stability is crucial, as even minor misalignments can lead to structural weaknesses. Considering the demands of modern construction, every detail matters.

Tip: Always assess the magnetic strength before use. Insufficient power may not provide the necessary alignment.

Additionally, insert magnets can eliminate the need for cumbersome brackets or supports. They simplify assembly, reducing labor costs and time. However, relying solely on these magnets isn't without risks. Environmental factors can affect their performance. Proper installation and frequent inspections are essential to ensure they function optimally.

Tip: Keep an eye on the environmental conditions. High humidity or extreme temperatures can impact magnet performance.

Incorporating insert magnets can dramatically improve stability. However, ensuring their reliability requires careful planning and inspection. The right approach can lead to better structural outcomes.

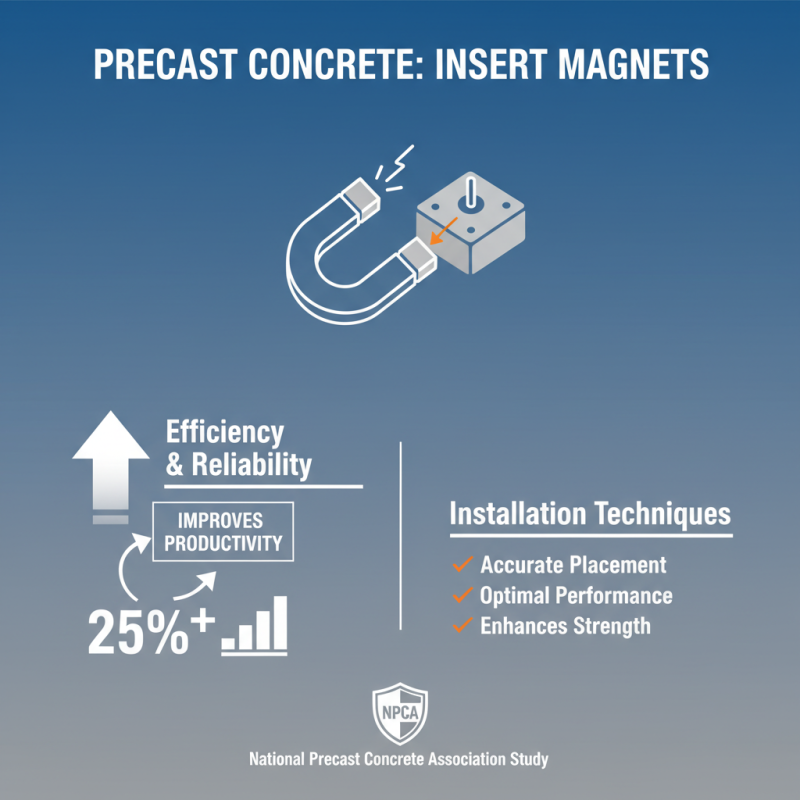

Insert magnets have become essential in precast concrete applications due to their efficiency and reliability. When installing these magnets, proper techniques can significantly enhance the strength of the concrete components. A study by the National Precast Concrete Association reports that the use of insert magnets can improve productivity by up to 25%. This highlights the importance of installation methods that ensure accurate placement and optimal performance.

Using a robust template is crucial during the installation of insert magnets. A template can help position the magnets precisely, reducing alignment errors. According to industry insights, an accurate alignment increases load-bearing capacities by an average of 15%. Additionally, securing the magnets with vibration techniques can improve adhesion, leading to better performance.

Despite their advantages, there are challenges. For instance, improper embedding can lead to premature failures in structural components. Installation teams sometimes overlook magnet orientation. Such oversights can detrimentally affect the magnet's efficacy. Continuous training and diligence are essential for mitigating these risks. The construction industry must commit to refining processes to achieve the best results with insert magnets in precast applications.

Insert magnets have emerged as a practical solution for precast concrete applications. They securely anchor components without damaging the surface. Compared to traditional fastening methods, insert magnets save time and reduce labor costs. Traditional methods often involve drilling, bolting, or welding. These can compromise the integrity of concrete and lead to structural weaknesses. It’s crucial to weigh the pros and cons of these techniques.

Inserting magnets into precast components is more efficient. The process is straightforward. Workers can easily reposition components without leaving marks. However, there can be variability in the effectiveness of magnets under different conditions. Some may find that the hold is not as strong in extreme temperatures. In contrast, traditional methods allow for a high degree of stability but require more effort and time. This creates tension in scheduling and productivity.

Cost is a significant factor. Insert magnets may have a higher initial cost, but the overall savings from quicker assembly should be considered. Some may hesitate, feeling uncertain about long-term reliability. In the end, the choice should depend on project-specific needs. Detailed analysis of each method is essential for achieving optimal results.