In the fast-evolving construction industry, the quest for efficiency and innovation has led to the emergence of revolutionary techniques such as Magnetic Shuttering Solutions. These solutions represent a significant advancement in the way formwork is utilized on construction sites. According to industry expert Dr. Emily Carter, a leading figure in construction technology, “Magnetic Shuttering Solutions not only enhance construction speed but also reduce labor costs, providing a compelling advantage for modern projects.”

The core principle behind Magnetic Shuttering Solutions lies in their ability to create a secure and adaptable formwork system that utilizes powerful magnets for quick setup and teardown. This technology streamlines the process of pouring concrete, making it more efficient than ever before. As construction demands continue to rise, understanding how these innovative solutions work becomes crucial for professionals in the field.

By implementing Magnetic Shuttering Solutions, contractors can experience improved accuracy and overall project turnaround times, setting a new standard for construction methodologies. As the industry continues to seek sustainable and cost-effective practices, the adoption of such advanced solutions may very well define the future landscape of construction.

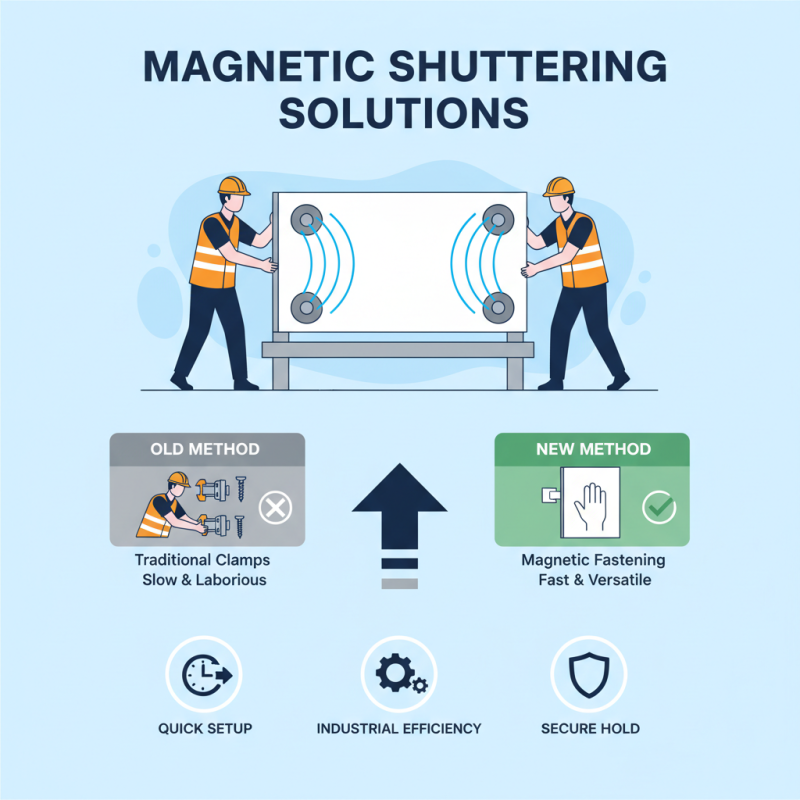

Magnetic shuttering solutions represent a cutting-edge approach to constructing temporary barriers in various industrial applications. These solutions utilize powerful magnets to securely hold panels in place, offering an innovative alternative to traditional shuttering methods. Unlike conventional systems that often rely on clamps or mechanical fasteners, magnetic shuttering provides a quick and versatile installation process. This is especially valuable in environments where time and efficiency are critical.

The primary advantage of magnetic shuttering solutions lies in their ease of use and adaptability. Installation and removal can be performed swiftly, allowing for rapid adjustments in response to changing project needs. Furthermore, the magnetic connection reduces the risk of damage to underlying surfaces, which is often a concern with traditional methods. Industry professionals increasingly turn to magnetic shuttering for projects in construction, film production, and manufacturing, where flexibility and speed are paramount. Overall, magnetic shuttering solutions are revolutionizing how temporary barriers are utilized, showcasing their effectiveness in diverse applications.

Magnetic shuttering systems represent an innovative approach in concrete prefabrication, advancing both efficiency and sustainability within the construction industry. Key components of these systems include magnetic panels, base plates, and magnetic switches, which work together to create a adaptable framework for concrete casting. The use of magnets allows for quick setup and repositioning of shuttering, significantly reducing labor time compared to traditional methods, where rigid forms are commonly used. A recent industry report highlights that integrating magnetic shuttering can lead to a reduction in concrete waste by up to 30%, thus supporting more sustainable building practices.

Moreover, the introduction of robots in the prefabrication process further enhances the advantages offered by magnetic shuttering solutions. As noted in emerging studies, automating the installation and adjustments of these systems can improve consistency and precision, which are critical for high-quality concrete components. The synergy between robotic technology and magnetic shuttering is predicted to increase productivity rates by at least 40% in prefabrication processes, enabling builders to meet growing market demands while minimizing their environmental footprint. Thus, magnetic shuttering systems not only simplify operational workflows but also align with the broader goals of sustainable construction.

Magnetic shuttering solutions utilize a unique mechanism that leverages the principles of magnetism to control light exposure in various applications, particularly in photography and cinema. The operation hinges on the activation of electromagnets that manipulate the physical shutters between the light source and the imaging sensor. When triggered, these magnets quickly and efficiently move the shutter mechanism, allowing for precise control over the timing and duration of light entry. This instant response is crucial in capturing high-quality images without motion blur, making it an increasingly popular choice in modern imaging equipment.

In essence, the magnetic shuttering mechanism simplifies the complex interplay of springs and levers found in traditional shutter systems. By replacing mechanical components with magnetic forces, these solutions enhance reliability and speed, which are paramount for both filmmakers and photographers. This type of framework not only improves the overall design but also offers greater durability, addressing common issues faced with aging infrastructure in imaging technology, much like the advancements seen in forms of falsework and formwork. The seamless operation of magnetic shutters represents a significant evolution in capturing the visual narrative.

This chart illustrates a comparison of key features of magnetic shuttering solutions, focusing on strength, weight, cost, ease of use, and durability. Each metric is rated on a scale from 0 to 100, providing insight into the performance characteristics of magnetic shuttering systems.

Magnetic shuttering solutions offer a modern and efficient approach to construction scaffolding, providing numerous advantages over traditional methods. One primary benefit is their remarkable ease of use. These systems employ magnetic forces to securely hold shuttering panels in place, allowing for faster setup and takedown. Builders can significantly reduce labor costs and time on site, maximizing productivity. Additionally, the absence of cumbersome clamps and ties decreases the risk of worker injuries associated with heavy equipment manipulation.

Another advantage lies in the adaptability these solutions provide. Magnetic shuttering can be utilized in various project scales and configurations, accommodating complex architectural designs effortlessly. This versatility means that constructors can implement them in any environment, ensuring a smooth workflow without sacrificing structural integrity. Moreover, the magnetic system contributes to enhanced precision in the alignment of panels, ultimately leading to more polished finishes.

**Tip:** To optimize the use of magnetic shuttering solutions, always ensure that the surface is clean and free from debris. Any contaminants can interfere with the magnetic grip, compromising safety and efficiency. Regularly maintain the magnetic components to sustain their effectiveness throughout the project lifespan.

Magnetic shuttering solutions have found numerous applications across various industries, serving as innovative tools for enhancing productivity and safety. In construction, these systems are often employed to create temporary barriers that protect workers and materials during concrete pouring. The strong magnetic forces enable the shuttering panels to quickly attach to steel surfaces, significantly reducing setup time and labor costs. This efficiency is particularly beneficial in large-scale projects where time is critical.

In the manufacturing sector, magnetic shuttering is utilized in processes such as casting and molding. By securely holding the molds in place, these solutions ensure precision in the formation of components, which is essential for meeting stringent quality standards. Additionally, industries such as aerospace and automotive benefit from magnetic shuttering during assembly operations. The ability to easily reposition or remove shuttering allows for greater flexibility when adapting to different production requirements, ultimately improving overall workflow and reducing downtime.