The construction industry constantly seeks innovative solutions to enhance efficiency and reduce costs. One such advancement is the 2100kg Precast Concrete Shuttering Magnet. This tool revolutionizes the way concrete is formed and molded. It provides a durable solution for securing shuttering systems in place while casting concrete structures.

With a robust holding capacity, the 2100kg Precast Concrete Shuttering Magnet ensures that panels remain stable throughout the pouring process. This stability not only improves the overall quality of the concrete but also speeds up construction schedules. Operators can save time and effort, leading to increased productivity on site.

However, there are challenges in using these magnets. Workers must be trained in their application, and misalignment can lead to issues. It's essential to reflect on best practices and safety protocols. Overall, the benefits of the 2100kg Precast Concrete Shuttering Magnet outweigh its drawbacks, paving the way for future advancements.

The 2100kg precast concrete shuttering magnet offers unique benefits in various construction applications. These magnets are known for their robustness and excellent holding strength. They are often used in creating large concrete structures where precision is critical. The high pulling force ensures that the forms remain secure during the pouring process. This reduces the risk of leaks and eliminates the need for cumbersome clamps.

In situations where time is of the essence, these magnets can be incredibly valuable. They allow for quick setup and repositioning, streamlining the workflow on job sites. However, great care must be taken to ensure they are placed correctly. Misalignment can lead to uneven surfaces, which may require additional work to correct. The ease of use also comes with the responsibility to double-check placements. Adjustments can be made smoothly, but neglecting these steps might lead to costly mistakes.

The ability to handle heavy loads makes these magnets ideal for large-scale projects. Yet, it’s essential to consider the site conditions. On uneven ground, additional support might be necessary. This can complicate the setup. Understanding the limitations of the equipment is crucial for successful application. Even with solid magnets, there should be a plan for unforeseen challenges.

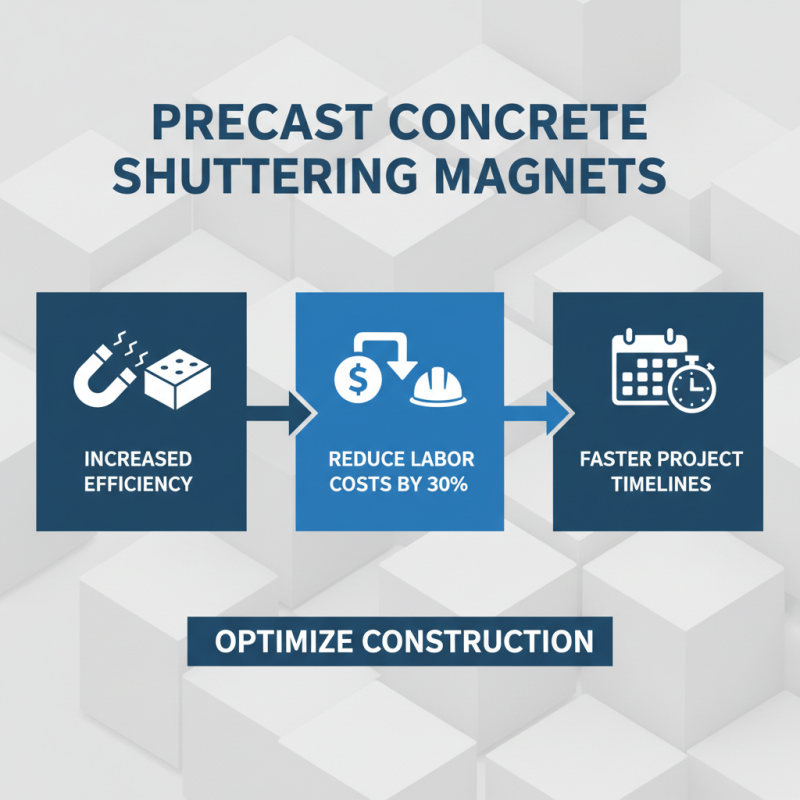

Precast concrete shuttering magnets offer numerous advantages in construction. Their efficiency can significantly reduce labor costs. According to industry reports, using magnet systems can save up to 30% on labor when setting up formworks. This reduction means crews can focus on other critical tasks, improving overall project timelines.

Another benefit is the precision they provide. These magnets hold formwork securely in place, ensuring correct alignment. Displacement during casting can lead to material waste. Studies show that precise formwork setups reduce concrete wastage by up to 15%. However, not all workers may be trained adequately to use this equipment. It’s essential to address training to maximize these benefits.

Flexibility is a key aspect of using shuttering magnets. They can adapt to different shapes and sizes of forms. This adaptability allows for innovative designs in projects. Construction teams often find this versatility beneficial. Although this technology is advanced, the initial costs can be a hurdle for some. Investing in training and tools may pose challenges that require careful consideration.

Shuttering magnets play a vital role in precast concrete construction. Understanding their design is key to harnessing their advantages. These magnets hold formwork securely in place, ensuring precise concrete placement. They facilitate quick assembly and disassembly, enhancing productivity on site. The strong magnetic force provides stability against forces of concrete pouring, reducing potential misalignments.

However, the design of these magnets can vary. Some may lack adequate strength or durability. In some cases, they might not adhere securely due to surface impurities. This can lead to mishaps during the concrete pouring process. The need for regular maintenance and inspection is crucial to ensure optimal performance. Failure to do so can result in increased costs and project delays.

Construction with shuttering magnets often requires skilled labor. Use can become inefficient without proper training. Understanding the specific application for each project is essential. This is where careful planning must take place. An appropriate choice in magnet design can significantly ease the construction challenges while enhancing the quality of the final product.

Shuttering magnets have gained traction as a modern solution for concrete formwork. Their appeal lies in efficiency. In a comparative study, shuttering magnets showed a 30% reduction in installation time compared to traditional methods like wooden formwork. Traditional methods often require significant labor and materials. The average installation time for wooden forms is about 8 hours per panel. In contrast, shuttering magnets can be installed in less than 6 hours.

Tips: Consider the site’s conditions when selecting between methods. Weather and site access can influence your decision.

Another interesting data point states that shuttering magnets can increase concrete placement efficiency by 25%. Traditional methods may not offer this benefit. Yet, they sometimes boast lower upfront costs. There’s a complexity in balancing initial costs versus long-term gains. Magnets reduce material waste, possibly leading to lowered overall project costs over time.

Tips: Always evaluate your project needs. Assess if the speed of shuttering magnets aligns with your timeline.

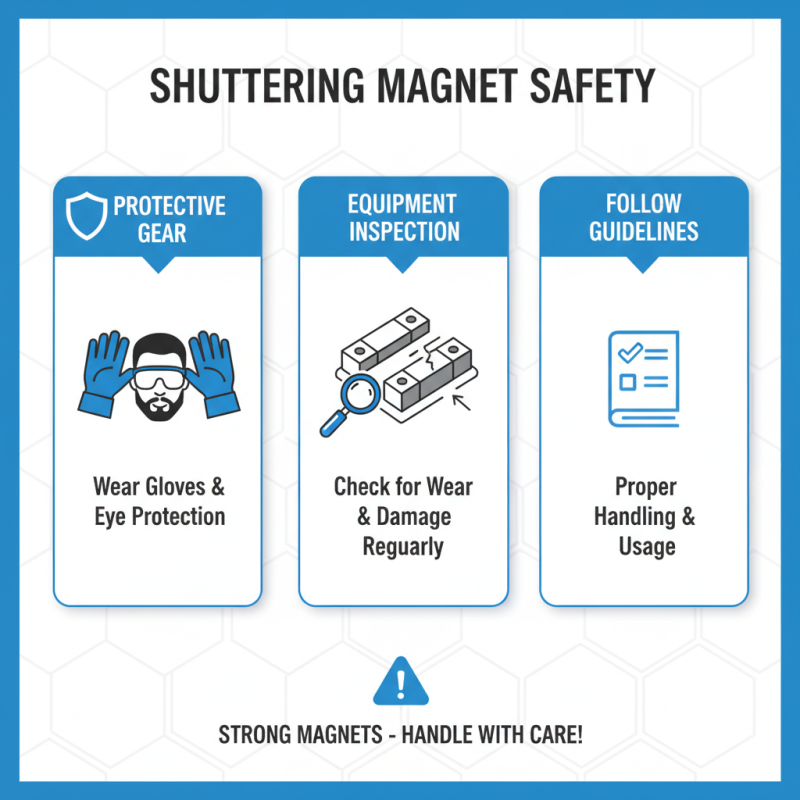

When considering the use of shuttering magnets, safety is paramount. These magnets are strong, able to hold precast concrete firmly in place. However, improper handling can lead to serious accidents. Workers should wear protective gear, including gloves and eye protection. Regular inspections of equipment are essential. Look for signs of wear or damage. It's crucial to follow guidelines to prevent failures.

Proper training is vital for all personnel. Employees must understand how to operate these magnets safely. Misuse can result in spillage or injury. Communication is key on job sites. Team members should signal before adjusting or moving any shuttering magnet. Ensuring everyone is on the same page can prevent needless risks.

Additionally, consider the weight load. Each magnet has a capacity limit. Overloading can cause the magnet to fail. Always double-check specifications before use. Using a magnet that can't handle the weight is a recipe for disaster. Evaluating the site conditions is also important. Uneven surfaces might lead to unstable placements. Address these issues before proceeding.