In the very avidly lenomd world of industry, lifting technologies have introduced and are poised to create a huge dent in operations as Wire Rope Thread Lifting Loops come in to take charge of construction, manufacturing, and even other sectors for that matter. A market report by MarketsandMarkets indicates that the global lifting equipment market will reach USD 63.9 billion by 2025 due to a steady increase in demand for lifting solutions that are safer and much more efficient. It gives e more load capacity as well as stability to reduce risks when using industrial lifting applications. The use of Wire Rope Thread Lifting Loops in already established systems should be quite a promising development as industrialists push towards more efficient and reliable processes.

As an established brand in magnetic fixing solutions, Xiamen Qianci Magnet Technology Co., Ltd. realizes how salient, reliable, and safe lifting mechanisms are to all. Our range includes Shuttering Magnets and Formwork Magnets, which fit into the arms of most demands nowadays on precast concrete production. We have taken Wire Rope Thread Lifting Loops, among other technologies, to enhance performance and step up the setting of new industry standards on safety and efficiency. As we head towards 2025, the merger will open the door for new possibilities in industrial operations with the coming together of cutting-edge lifting technologies and advanced magnetic solutions.

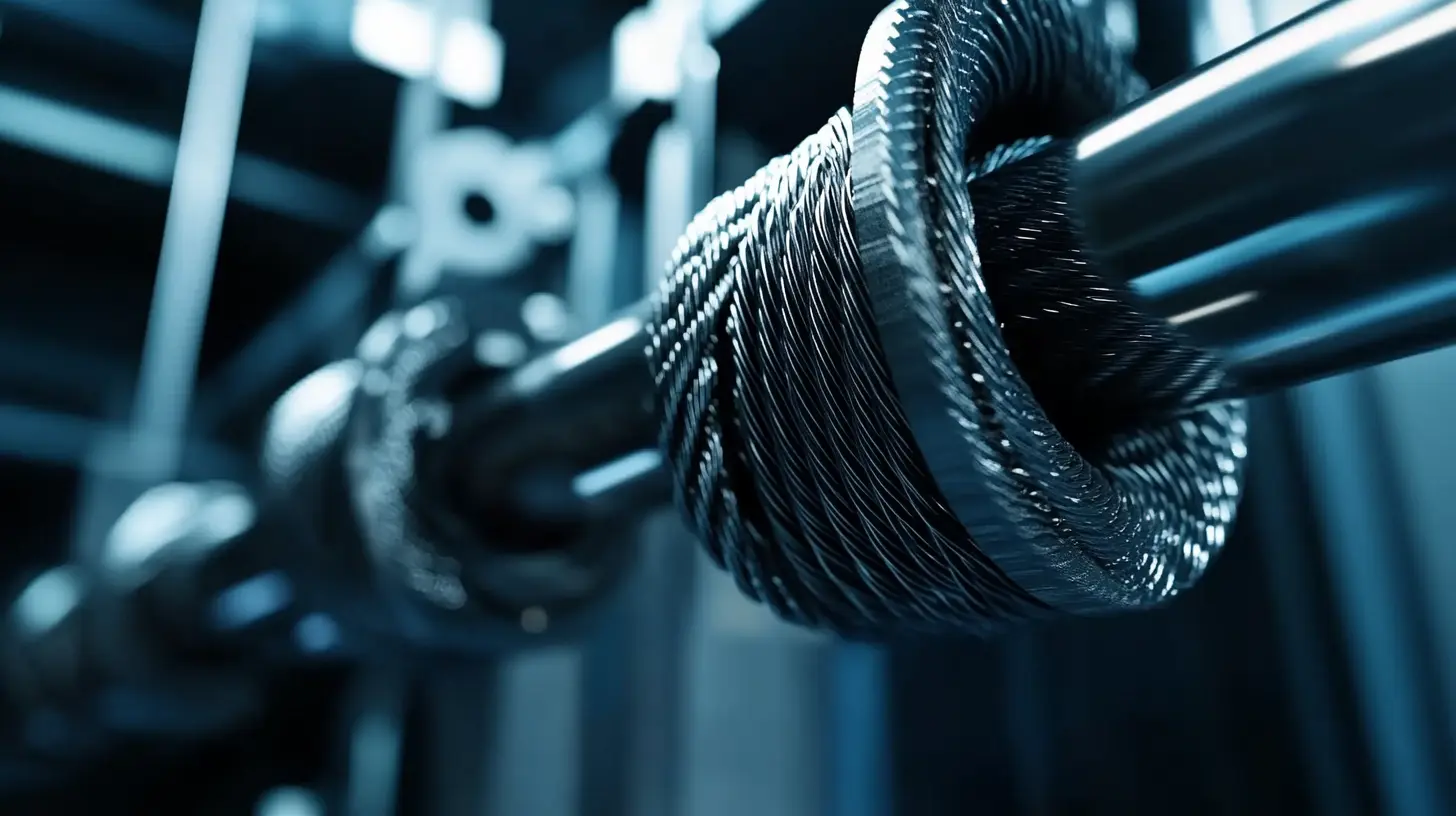

With advances increasing efficiency and safety in lifting, wire rope technology has undergone transformations in its brief histories. Wire rope, as an aid in innovation, was thus first introduced in the 19th century to allow the lifting of heavier loads with greater ease than any competing methods. The continued development of wire ropes resulted in better materials and related engineering design, producing products of higher strength and in a lighter weight allowing greater payloads for safer handling. As we head towards 2025, wire rope thread technology marks a giant leap in industrial lifting solutions. The futuristic approach envisions a relook at how heavy lifting is done across the full spectrum of industries, including construction, manufacturing, and logistics. The new wire rope designs will use advanced technologies, enhanced tensile strength, and fatigue resistance to withstand harsher operational environments and deliver optimum efficiency. At the same time, the push for technology innovation is reflected in international initiatives aimed at removing hindrances to scientific progress. Countries like Vietnam are implementing new policies to promote technological breakthroughs conferring the notion interest in scientific development as a pathway for increased productivity and economic growth. This shared commitment to innovation links this development in wire rope technology as not merely an engineering problem but a vital player in the grander narrative of industrial emancipation in the near future.

Innovations in wire rope thread technology propel new horizons of industrial lifting as 2025 is bound to usher in an exciting era where durability and efficiency in lifting will stand in sharp contrast to yesterday's heavy lifting concepts infused by industry automation. The emphasis in newly constructed designs is placed on the thread design, thus increasing grip and minimizing wear in very harsh working conditions.

At CES 2025, lunar construction machinery concepts provide a fascinating convergence of wire rope technology and extraterrestrial construction. As industries gaze beyond our terrestrial confines, the demand for reliable, high-performance lifting solutions enters center stage. Advanced wire rope threading techniques ensure that machinery remains safe and operable in stressing conditions-from low gravity to harsh climates.

In addition, being able to automate underwater and extraterrestrial construction processes requires them to have the innovation promise. The groundbreaking technologies in wire rope thread technology assure that the machinery will be designed to smoothen processes, thus reducing downtime and expanding the realms of the possible in both terrestrial and cosmic engineering. It would be quite fascinating to see how the above inventions will change the industrial face forward, ushering in the unparalleled feats in construction and lifting applications.

This new and improved wire rope threading technology will redefine industrial lifting applications by the year 2025, bringing in many benefits that would make things safe and efficient. A report by the International Journal of Industrial Engineering states that almost 25% of the injuries in workplaces are consequence of lifting, most of which find their causes due to machinery defect or improper usage of lifting machines. Enhanced wire rope threading goes a long way in greatly reducing such risks, making for a better and tighter fit, which in turn sustains load stability and reduces slippage.

Most interestingly, this new technique will also improve load capacity and durability for wire ropes. According to American Society of Mechanical Engineers research, the tensile strength of wire rope can be improved using better threading methods by as much as 30%. That means industry can, henceforth, handle more, because a higher load can be tolerated under the existing safety standards. Wire ropes can also run for as much as 40% longer, which means they need much less maintenance and downtime on operations that have a vital input to the industries' productivity.

This enhanced wire rope threading technology enhances safety and cost savings by automating an increasingly larger part of industrial applications. With Industry 4.0, smart lifting systems can—and will—integrate advanced sensors and data analytics into these threading processes, freeing lifting activity from its place and allowing real-time monitoring of lifting equipment performance. Such an integration is surely destined to elevate operational efficiency and build a transforming prototype for the next generation in terms of safe and intelligent industrial lifting.

The research surrounding traditional vs. modern wire rope techniques monitors a considerable shift in lifting processes within the industry, with wire rope thread technology entering the production scene. Traditional rope systems have been working for various industries for several decades; however, sometimes these systems fail due to their heaviness and less flexibility, leading to getting worn and torn. Therefore, the majority of the elements used here are mechanical and require manual work, making these systems slow and labor-intensive.

However, modern wire rope thread technology presents new materials and structural designs that are performance-and-safety-optimized. New wire rope technology can produce light and strong lifting solutions for heavy lifting, thereby reducing the odds of operator fatigue. Automated systems combined with advanced engineering techniques dramatically improve productivity levels and decrease the likelihood for accidents associated with methods of the past.

One of the crucial factors addressed during these comparative studies is the inclusion of intelligent wire ropes with real-time monitoring. This allows the operators to monitor performance measures and troubleshoot any potential problems, which could otherwise lead to failure. Since industries are progressing towards automated processes, adapting modern wire rope technologies will be key for companies aiming to remain competitive and guarantee safe lifting operations.

Clearly, the application of wire rope threading technologies in industrial lifting operations is revolutionary, furthering advancements in efficacy and safety. Several corporations have successfully implemented this newly advanced technology, which can revolutionize operations. A case study worth mention is that of a leading construction company that incorporated advanced thread technology into its lifting mechanisms: the benefits included optimizing load-bearing capacity and minimal wear and tear on the equipment, resulting in a massive reduction in downtime and maintenance expenditures.

A further interesting case is from the offshore oil industry, which has already employed wire rope thread technology to improve reliability of lifting systems in harsh environments. A case study revealed that by utilizing this new technology, the firm was able to achieve higher safety standards while improving operational efficiency. The increased safety standards were achieved for example by using threaded wire ropes for more precise load handling, which is arguably an important contributor to preventing accidents and improving worker safety.

The adoption of this wire rope thread technology by an automobile maker has led to significant successes within that industry as well. The technology was deployed by one of the top automotive manufacturers on some of its assembly lines, resulting in even more continuous production and much reduced incidence of poor quality. Superior lifting precision for heavier components not only streamlined operations but also contributed to a safer working environment for factory workers. Clearly, successful implementations such as these underscore wire rope thread technology's transformational impact across industries, while concomitantly solidifying itself for broader adoption into the future.

AI technologies and other automation systems are the lifeblood of any emerging sector today; this has become obvious from recent market trends. Demand generation within markets such as steel and manufacturing calls for an innovative lifting solution that balances efficiency and safety. A great deal of synergy between AI and industrial manufacturing could ensure better operational efficiency in light of the challenges presented with information security in control systems.

Advanced technologies such as AI-based vision solutions and simulation tools are only reinforcing these opportunities for organizations willing to change. Organizations are finding that AI helps make operations more efficient and improves safety and decision-making in industrial settings. The concept of the industrial metaverse, meanwhile, serves as a place where traditional lifting solutions can face opportunities and challenges as companies experiment with different modes of collaboration and data sharing. The adoption of wire rope thread technology and AI shall therefore be central to the next wave of innovation for lifting solutions as industrial patrons could be prepared for the trials of a fast-changing market.

The industrial lifting industry will undergo transformation in the year 2025, all on account of excellent new developments in wire rope technology. Experts across the industry have alluded to these changes as being something that can redefine safety, efficiency, and longevity in lifting solutions. In a recent report by Industrial Insights, the projection for the global advanced lifting technologies market is set at $9.5 billion by 2026, making this an urgent call for industries to embrace modern-day alternatives.

Leaders in the industry claim that the new wire rope thread technology not only provides better tensile strength but also reduces wear and tear during operations. According to a recent study carried out by the Lifting Equipment Manufacturers Association (LEMA), the implementation of this technology could enhance operational life by up to 30%, sharply cutting maintenance costs and downtime. "If we are to stay competitive, adopting such technologies is not an option anymore; it is a must," emphasizes Dr. Emily Carter, a leader in lifting solutions.

In fact, smart sensors coupled with wire rope systems are poised to revolutionize how companies track and manage their lifting operations. The sensors provide real-time data analytics to improve safety and operational efficiency, as reported by the World Crane and Lifting Safety Organization (WCLSO)."The technology allows us to foresee potential failures before such things happen, saving a life and saving some money," argues Mark Reynolds, LiftSmart Solutions CEO.

Industrial lifting is changing rapidly, and one emerging signature revolution is wire rope thread technology. By 2025, sustainability and safety form ever-important pillars in this innovative application, particularly concerning green lifting solutions. Wire ropes, the linchpin in lifting systems, are undergoing a paradigm shift for designing them cleaner and safer.

Technology advancement takes extrusion of wires, not only strength and durability factors but also positively affects heavy lifting tasks by minimizing their ecological footprint. The use of recyclable materials in their fabrication processes makes sure wire ropes serve the cause of a greener future in industries. This move includes compliance with existing environmental regulations and does not differ from corporate sustainability goals, thus increasing the business motivation for improving its green credentials.

Safety must be kept in priority, as well, under any lifting operation. The latest wire rope patterns introduce highly advanced attributes with a better load capacity and extreme wear resistance. This makes them provide additional safety by lowering the risk of accidents and failures in equipment operations. Industries should adopt these latest technologies to ensure that lifting practices are much safer while enjoying an environmentally responsible framework. With this in mind, wire rope developments are awaited to redefine industrial lifting in a social and ecological mindful way, as organizations come together toward valuable green and safe goals.

Wire rope technology emerged in the 19th century, enabling the lifting of heavier loads with greater ease compared to traditional methods.

By 2025, wire rope thread technology is expected to revolutionize industrial lifting solutions, incorporating advanced design for improved tensile strength and fatigue resistance.

Countries like Vietnam are implementing new policies to foster technological breakthroughs, promoting innovation that enhances productivity and economic growth.

Enhanced wire rope threading significantly reduces risks associated with lifting operations by providing a tighter, more secure fit, which decreases slippage and improves load stability.

Improved threading techniques can enhance the tensile strength of wire ropes by up to 30%.

The integration of enhanced wire rope threading can extend the lifespan of wire ropes by up to 40%, reducing maintenance needs and operational downtime.

Enhanced wire rope threading aligns with the automation trend in Industry 4.0, allowing for the integration of smart lifting systems with sensors and data analytics for real-time monitoring.

The evolution of wire rope technology not only boosts safety and cost-efficiency but also plays a significant role in the broader narrative of industrial transformation through technological innovations.