In the modern construction industry, efficiency is paramount. Magnetic Formwork Products are gaining traction for their innovative design and ease of use. According to a report by the International Journal of Construction Management, projects using magnetic formwork can reduce labor costs by up to 30%. This efficiency translates into faster project completion times and increases return on investment.

These products offer flexibility and adaptability that traditional formwork cannot match. They simplify the process of shaping concrete structures, reducing the need for multiple tools and materials. However, not all magnetic formwork solutions are created equal. Some products may lack durability or require extensive training to utilize effectively. The industry must continually evaluate and improve these offerings to maximize their potential.

Furthermore, the adoption of Magnetic Formwork Products can lead to challenges. Some construction teams might resist changing established practices. Investing in new technologies requires careful consideration. Ultimately, balancing innovation with practicality is crucial in this evolving sector. Engaging with diverse products can pave the way for future advancements while reflecting on potential drawbacks will lead to better choices.

Magnetic formwork technology is revolutionizing the construction industry. This innovative solution streamlines the building process. It eliminates many traditional challenges faced during construction. The magnetic approach facilitates faster assembly and disassembly of formwork. Workers can produce high-quality concrete structures with consistent shapes.

Using magnetic formwork can significantly improve project efficiency. It allows for precise alignment and positioning. The flexibility of this technology helps accommodate various designs. It makes it easier to adapt to changing project requirements. However, understanding the limitations is crucial. Some projects may require additional support to ensure stability.

Tips: Always conduct a thorough assessment before implementation. Evaluate the specific needs of your project. Workers need training to maximize the potential of magnetic formwork. Proper maintenance can extend the lifespan of products. It’s important to remain open to learning and adapt techniques as needed.

| Product Name | Material | Dimension (mm) | Weight (kg) | Feature |

|---|---|---|---|---|

| Modular Magnetic Panel | Steel | 1200 x 600 | 30 | Quick assembly |

| Flexible Magnetic Form | Plastic | 1500 x 300 | 20 | Adaptable shapes |

| Heavy-Duty Magnet Frame | Aluminum | 2000 x 1000 | 45 | High strength |

| Compact Magnetic Block | Reinforced Plastics | 500 x 500 | 10 | Space-saving |

| Adjustable Magnetic Shims | Metal | 300 x 100 | 5 | Customizable height |

| Wall Form Magnet | Steel | 1000 x 300 | 18 | High holding force |

| Universal Magnetic Connector | Plastic with Steel Insert | 200 x 200 | 3 | Easy connection |

| Heavy-Duty Base Magnet | Cast Iron | 100 x 100 | 25 | Stable base |

| Vertical Form Magnet | Plastic | 800 x 400 | 15 | Vertical surface support |

| Lightweight Magnetic Sheet | PVC | 1200 x 1000 | 22 | Flexible installation |

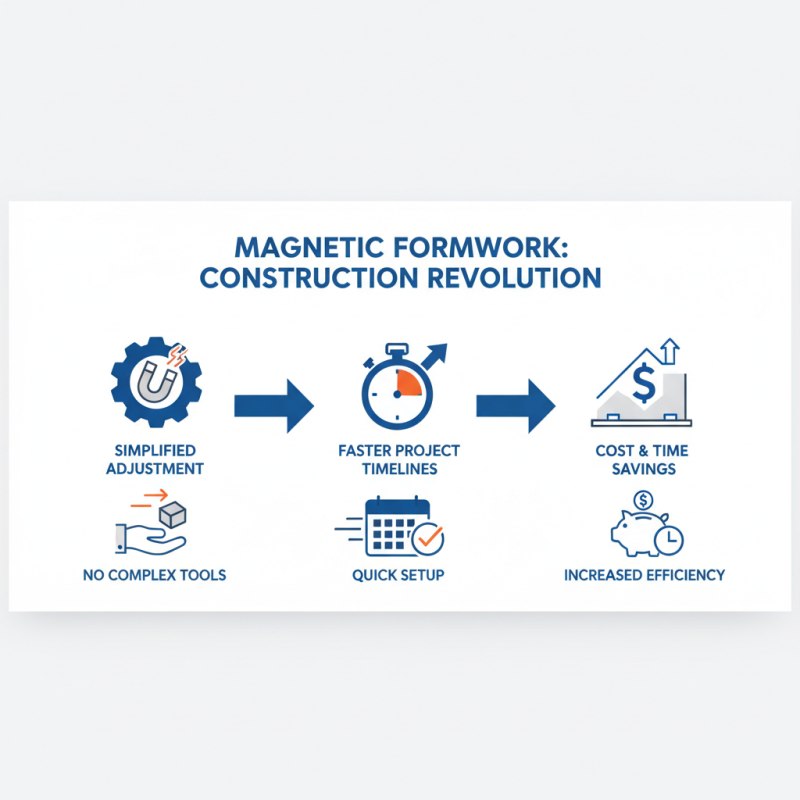

Magnetic formwork products are revolutionizing the construction industry. They offer several key benefits that enhance efficiency on job sites. One major advantage is their simplicity. Workers can easily adjust these forms without complex tools. This quick setup leads to faster project timelines. Time saved means money saved, a significant consideration for any construction manager.

Another benefit is precision. Magnetic forms consistently offer accurate shapes and dimensions. This attention to detail reduces errors during the pouring process. With fewer mistakes, project teams often avoid costly rework. However, reliance on this technology can pose risks. For example, improper application or adjustments could lead to structural issues.

Furthermore, these forms are often reusable. This reduces waste and is an eco-friendly option. Yet, some construction teams might underestimate their durability. Relying too heavily on magnetic systems without proper maintenance can lead to failures. Overall, while magnetic formwork enhances efficiency, careful consideration is necessary for long-term success.

Magnetic formwork products have revolutionized construction efficiency. These tools streamline the process of creating concrete structures, allowing for faster setups and installations. With magnetic edges, they secure quickly to steel surfaces, minimizing labor costs while maximizing effectiveness. Workers can adjust and reposition them easily, which saves valuable time on the job site.

In practice, the advantages are clear. Construction teams report fewer errors during the pouring process. The ability to create seamless joints reduces the need for extensive finishing work. Yet, it is essential to recognize that quality control remains a challenge. Not all configurations suit every project, leading to potential setbacks if not properly assessed.

Detailing the specific products can guide choices further. Some forms are ideal for straight walls, while others excel in complex shapes. Visible inaccuracies can emerge when magnets lose strength or panels misalign. Builders must approach these products critically, weighing their benefits against their limitations to ensure optimal results.

Magnetic formwork has gained popularity in the construction industry due to its efficiency and versatility. When comparing the various options available, several factors come into play. Material quality, ease of use, and safety features can significantly affect performance. It’s vital to analyze the different products to find the best fit for specific construction needs.

When evaluating magnetic formwork, keep in mind that not all products perform the same. Some materials may warp under pressure, impacting the final structure. The ability to align accurately is also essential. A misaligned formwork can lead to costly renovations. Pay attention to magnetic strength; weaker magnets can result in formwork shifting during concrete pour.

Tip 1: Look for user reviews that highlight real-life experiences with alignment issues.

Lastly, consider weight and portability. Heavy formwork may require additional machinery, adding to costs and labor. Conversely, very lightweight options may compromise stability. Test the balance between weight and strength to optimize efficiency.

Tip 2: Experiment with different products on smaller projects before committing long-term.

Choosing the right magnetic formwork can significantly enhance workflow, but careful consideration is crucial to avoid costly mistakes. The right decision can make all the difference.

In recent years, magnetic formwork solutions are evolving rapidly in the construction industry. These products streamline the building process, offering flexibility and efficiency. Construction teams are embracing innovative designs that combine advanced materials with user-friendly features. Such tools minimize waste and reduce labor costs. This efficiency is vital in today's fast-paced construction environment.

Emerging trends in magnetic formwork focus on sustainability. Using eco-friendly materials can significantly lessen the environmental impact. There's a growing interest in systems that allow for easy reuse after projects are completed. A balance between functionality and sustainability is crucial. It can be challenging to maintain durability and efficiency while prioritizing eco-friendly choices. Striking this balance requires ongoing innovation and collaborative efforts among engineers and designers.

Additionally, the customization of magnetic formwork is gaining traction. Tailored solutions can fit unique project requirements, but this may complicate standardization efforts. The flexibility offered by modified designs may lead to inconsistencies in production quality. It's a critical area that needs attention. This highlights the need for skilled professionals who can navigate these challenges effectively while ensuring the best outcomes for construction projects.

This chart illustrates the ratings of various criteria for the top magnetic formwork products in the construction industry. Each dimension reflects the importance of features that contribute to efficiency and performance in building projects.