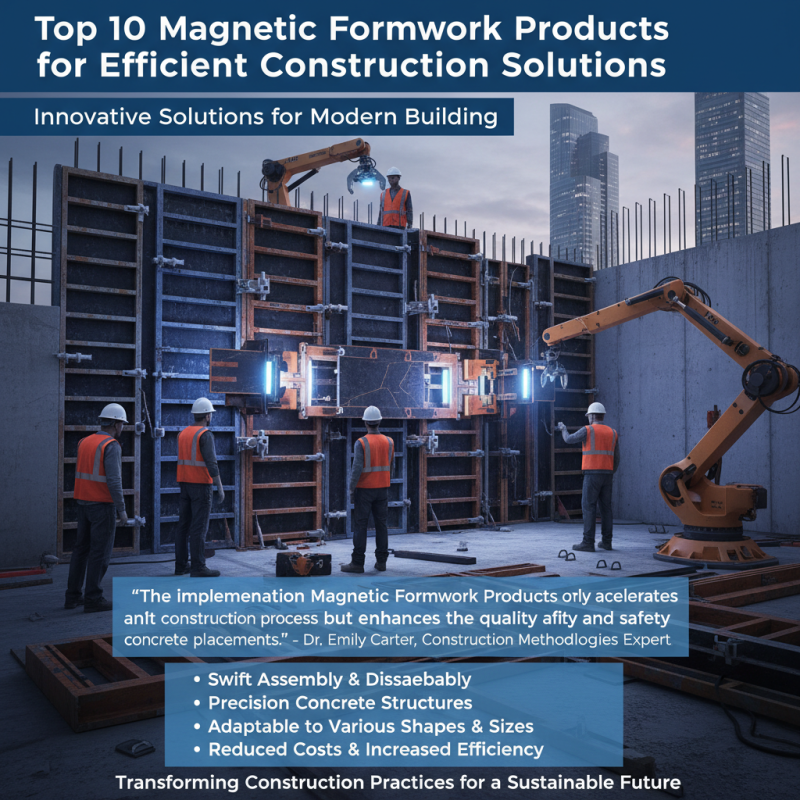

In the evolving landscape of construction technology, the significance of Magnetic Formwork Products has garnered considerable attention among industry professionals. As construction projects demand increased efficiency and reduced costs, magnetic formwork emerges as a game-changing solution, enabling swift assembly and disassembly while ensuring precision in the formation of concrete structures. According to Dr. Emily Carter, a renowned expert in construction methodologies, "The implementation of Magnetic Formwork Products not only accelerates the construction process but also enhances the quality and safety of concrete placements."

As we explore the top 10 Magnetic Formwork Products available on the market today, it is essential to recognize the innovative advancements that these products bring to construction practices. With the ability to adapt to various shapes and sizes, magnetic formwork is proving to be indispensable for many contractors aiming to streamline their operations while maintaining high standards of workmanship. This introduction will delve into the leading magnetic formwork solutions, shedding light on their features, benefits, and the transformative impact they have on modern construction projects. Whether it's for residential buildings, commercial structures, or infrastructural developments, the adoption of Magnetic Formwork Products represents a pivotal shift towards more efficient and sustainable construction solutions.

Magnetic formwork technology is revolutionizing the construction industry by introducing a level of efficiency and adaptability that traditional methods struggle to match. Utilized primarily for casting concrete, magnetic formwork utilizes powerful magnets that securely adhere to steel surfaces, allowing for quick setups and reconfigurations on-site. According to recent industry reports, the implementation of magnetic formwork can reduce assembly time by up to 50%, ultimately leading to faster project completions and decreased labor costs. Furthermore, the versatility of magnetic formwork allows for complex designs that were previously challenging or time-consuming to achieve, thereby expanding creative possibilities for architects and engineers alike.

When considering magnetic formwork solutions, it’s essential to understand the benefits they offer beyond just time savings. The adaptability of these systems not only minimizes waste by allowing multiple uses for the same components but also fosters enhanced safety on construction sites. Using fewer materials and achieving a seamless finish decreases the likelihood of defects, ultimately improving reliability.

Tips for successful integration of magnetic formwork include conducting thorough site assessments to ensure compatibility with existing structures and investing in proper training for workers to maximize efficiency. Additionally, leveraging digital design tools alongside magnetic formwork can further streamline the concrete pouring process, aligning construction practices with modern technological advancements. Embracing these innovations is a key step toward achieving sustainability and efficiency in construction projects.

This bar chart illustrates the efficiency of different magnetic formwork products based on their average installation time (in hours) and reusability (in cycles). This data demonstrates the advantages of magnetic formwork technology in optimizing construction processes.

Magnetic formwork products have revolutionized the construction industry by offering a range of benefits that enhance efficiency and effectiveness in building projects. One of the primary advantages of these products is their incredible ease of use. Unlike traditional formwork, which often requires extensive assembly processes, magnetic formwork can be quickly set up and adjusted, saving both time and labor costs. This rapid deployment not only accelerates project timelines but also allows for greater flexibility in design, as the forms can be easily repositioned to accommodate various project requirements.

Another key benefit is the precision and consistency that magnetic formwork provides. The strong magnetic properties ensure that forms stay firmly in place during the pouring and curing of concrete, leading to more accurate and uniform finishes. This reliability reduces the risk of defects, minimizing the need for costly rework. Additionally, the durability of magnetic formwork materials contributes to their reusability, making them a sustainable option that reduces waste. Overall, the use of magnetic formwork products can result in improved project outcomes and significant cost savings, making them an appealing choice for modern construction solutions.

Magnetic formwork systems have revolutionized the construction industry by providing efficient and precise solutions for creating concrete structures. By utilizing magnetic forces, these formwork products offer a unique way to secure and reposition forms quickly, which significantly reduces labor costs and construction time. The ability to adapt to various shapes and sizes also enhances the productivity of construction teams, allowing for more complex designs without the need for extensive setup processes.

When implementing magnetic formwork solutions, it’s important to consider a few key tips. Firstly, always ensure that the surface where the magnets will be used is clean and free of debris. This will ensure a stronger hold and prevent any accidental shifts during the pouring process. Secondly, evaluate the weight distribution of your formwork; ensuring that heavier panels are supported adequately will prevent potential mishaps. Lastly, training your team on the optimal use of magnetic systems can further improve efficiency and worker safety on the job site.

Overall, embracing magnetic formwork can significantly drive productivity in construction projects. By prioritizing effective methods and operations, teams can deliver high-quality results while maintaining an efficient workflow. In the fast-paced world of construction, these innovative products are transforming traditional approaches and setting new standards for excellence.

Magnetic formwork systems have revolutionized the construction industry by offering efficient and versatile solutions. Among the top products, several features set them apart, enhancing usability and performance. For instance, ease of setup is a primary consideration, as some systems boast rapid assembly and disassembly, reducing labor costs and project timelines. Additionally, the weight and size of the magnetic panels influence the handling and transportation of the formwork, making lightweight options particularly favorable for site mobility.

Another critical aspect is the durability of the materials used in the magnetic formwork products. High-quality options resist wear and tear, ensuring a longer lifespan and consistent performance over multiple projects. The versatility in design capabilities also reflects significant advantages; for instance, many products allow for customized shapes and sizes, enabling builders to adapt to various architectural requirements seamlessly. Furthermore, the magnetic locking mechanism provides stability and precision, minimizing the risk of misalignment during the pouring process, which is crucial for achieving high-quality concrete finishes.

| Product Name | Weight (kg) | Dimensions (cm) | Load Capacity (ton) | Material | Magnet Strength (N) |

|---|---|---|---|---|---|

| Formwork A | 40 | 120 x 60 x 5 | 12 | Steel | 900 |

| Formwork B | 35 | 100 x 50 x 6 | 10 | Aluminum | 850 |

| Formwork C | 50 | 150 x 75 x 7 | 15 | Composite | 950 |

| Formwork D | 45 | 130 x 65 x 5 | 11 | Steel | 800 |

| Formwork E | 30 | 90 x 45 x 6 | 8 | Aluminum | 750 |

| Formwork F | 48 | 140 x 70 x 7 | 13 | Composite | 920 |

| Formwork G | 38 | 115 x 55 x 5 | 9 | Steel | 840 |

| Formwork H | 53 | 155 x 80 x 8 | 17 | Composite | 970 |

| Formwork I | 42 | 125 x 62 x 5 | 14 | Steel | 890 |

| Formwork J | 37 | 95 x 48 x 6 | 7 | Aluminum | 780 |

The trend towards magnetic formwork innovation is rapidly reshaping the construction industry, offering a streamlined approach to concrete placement and structure formation. As reported by industry analysts, the global formwork market is expected to reach USD 13 billion by 2025, with magnetic formwork systems accounting for a significant portion of this growth. This shift is driven by the increasing demand for sustainable and efficient construction solutions. Magnetic formwork allows for quicker setup and teardown operations, which can reduce labor costs by up to 30%, according to recent studies. Moreover, the accuracy and reusability of these systems contribute to reduced material waste, aligning with green building initiatives.

Future applications of magnetic formwork are likely to diversify beyond traditional uses. Innovations in smart technology integration, such as sensors and automation, are set to enhance the functionality of these systems. By incorporating real-time data tracking and load monitoring, construction teams can optimize concrete pouring processes, ensuring quality and safety. Research suggests that adopting such advanced technologies could increase overall project efficiency by 25% or more, making magnetic formwork not just a trend but a critical component in the future of construction. As sustainability and efficiency become paramount, magnetic formwork will play an essential role in meeting these evolving industry demands.