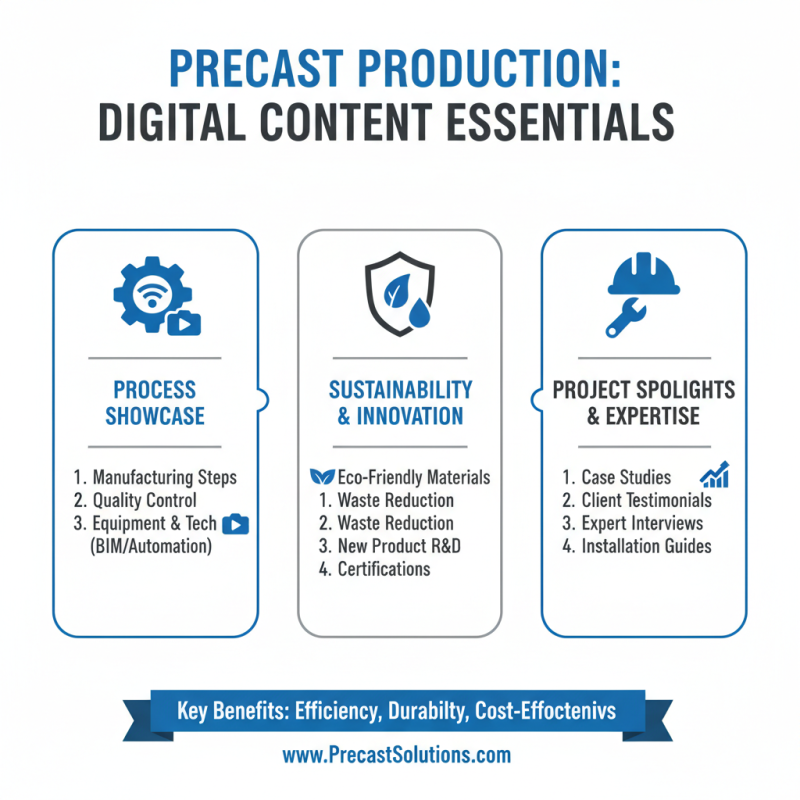

In the precast production industry, selecting the right tools is vital. Shuttering magnets for precast production stand out as essential devices. John Smith, a renowned expert in construction technology, states, "Effective use of shuttering magnets can significantly enhance productivity." His insight sheds light on the importance of these magnets in streamlining operations.

Shuttering magnets provide strong hold and adaptability, which simplifies the casting process. They allow for quick setup and alignment of formwork. This efficiency reduces labor costs and increases output. However, some producers underestimate maintenance, impacting the overall effectiveness of these tools. Neglecting this aspect can lead to errors in production and increased costs.

Navigating the selection of shuttering magnets for precast production can be challenging. There are various types available, each with unique benefits. Understanding these differences is crucial for optimal use. As the industry evolves, producers must evaluate their choices continually. Balancing quality with innovation will determine success in precast production.

When it comes to precast production, shuttering magnets play a crucial role. These tools simplify the process of forming concrete structures. They provide the necessary support and alignment for molds, ensuring precision. How these magnets are utilized can greatly enhance productivity and improve safety.

Shuttering magnets are known for their strength. They keep the mold firmly in place during the pouring process. This reduces the chances of leaks or misalignments. However, some teams may not fully understand their potential. Not using the right size or type can lead to failures. It's essential to assess needs before selecting magnets.

Moreover, the installation can be tricky. Improper placement might lead to complications. It’s crucial to train staff properly. Even with high-quality magnets, accidents can happen. Reflecting on past projects can help teams avoid mistakes. Continuous improvement in techniques will yield better results. Ultimately, understanding these details is vital for success in precast production.

Shuttering magnets play a vital role in precast concrete systems. They enable quick assembly and reconfiguration of formwork. Recent studies indicate that using these magnets can improve productivity by up to 30%. This efficiency leads to faster project completion.

Functionality is crucial. Shuttering magnets hold formwork securely, ensuring precise concrete pouring. An industry report highlights that precise formwork placement can reduce waste by about 15%. However, improper use of these magnets can lead to misalignment. This may result in costly errors and project delays.

The ease of use is one of the key benefits. Workers can reposition magnets quickly, which minimizes downtime. Despite this, not all magnets perform equally. Some may struggle with strength under heavy loads. Regular checks and maintenance are essential for optimal performance. Addressing these issues is necessary for maximizing the benefits of shuttering magnets.

Shuttering magnets play a crucial role in precast production. They enhance efficiency and ensure precision in casting shapes. These tools simplify the alignment of molds, reducing human error. When magnets hold the forms securely, the production process becomes smoother. Workers can focus on other tasks, boosting overall productivity.

Another benefit of using shuttering magnets is their versatility. They work with various mold materials and can be adjusted easily. This flexibility allows factories to meet varying design specifications without major changes. However, not all magnets are created equal. Some may lose strength over time or may not hold well on uneven surfaces. Regular checks are essential to ensure optimal performance.

Cost-effectiveness is yet another key aspect. Investing in quality magnets can reduce material wastage. Precise mold placement leads to fewer defects in the final products. But it's important to weigh costs versus benefits. Some magnets may seem cheap initially but could lead to higher expenses due to failures. Therefore, a well-thought-out choice is necessary for long-term success.

| Magnet Type | Hold Force (lbs) | Material Compatibility | Key Benefit |

|---|---|---|---|

| Standard Shuttering Magnet | 400 | Steel | High holding strength |

| Heavy Duty Shuttering Magnet | 800 | Steel, Reinforced Concrete | Durability under heavy loads |

| Compact Shuttering Magnet | 300 | Steel | Space-saving design |

| Quick Release Magnet | 500 | Steel | Easy removal |

| Adjustable Shuttering Magnet | 600 | Steel | Versatility in applications |

| Vacuum Shuttering Magnet | 350 | Smooth Skim Coated surfaces | Effective on non-magnetic surfaces |

| U-Shaped Shuttering Magnet | 450 | Steel | Improved edge retention |

| Lifting Shuttering Magnet | 700 | Steel | Ease of handling heavy panels |

| Double-Sided Shuttering Magnet | 550 | Steel | Efficient use of space |

| Flexible Shuttering Magnet | 400 | Steel, Various substrates | Adaptability to different shapes |

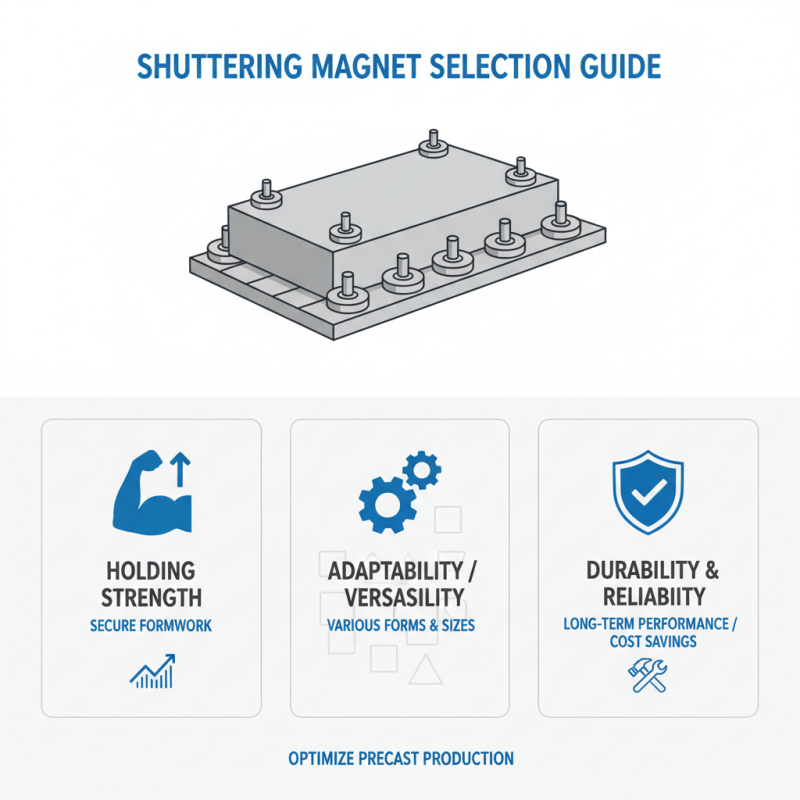

When selecting shuttering magnets for precast production, several key factors come into play. First, consider the magnet's holding strength. A magnet must be strong enough to securely hold formwork in place. Industry reports indicate that holding strength can vary significantly among products. Choosing a magnet with inadequate strength could lead to costly errors.

Next, assess the ease of use. Some magnets require complex installations, while others offer user-friendly designs. Ease of handling can reduce labor costs during production. Think about the versatility of the magnet too. A good magnet should work with various forms and surface materials. Inadequate adaptation to different conditions can lead to inefficiencies.

Tip: Always check load specifications against your project requirements. It is essential to avoid underestimating the demands of a project.

Lastly, pay attention to durability. Shuttering magnets experience significant wear. They must withstand harsh working environments. Investing in high-quality materials can save money in the long run. Evaluate the feedback from other users about performance over time.

Tip: Regular maintenance can extend the life of your magnets. Routine checks can avoid sudden failures.

When evaluating shuttering magnets for precast production, several key factors come into play. The strength of a magnet is paramount. A stronger magnet ensures stability, reducing the risk of accidents during the casting process. Some products may promise high strength but fail under real conditions. Users often report discrepancies between advertised and actual performance. It’s crucial to test these magnets in your specific production environment.

Another important aspect is ease of use. Some magnets feature attachments that simplify setup and removal. However, certain designs can be cumbersome. A magnet that looks efficient may actually require more time and effort to handle. This becomes an obstacle during high-demand projects. Durability is equally critical. Some magnets degrade quickly, especially in harsh working conditions. Users should consider the long-term cost implications of relying on less durable options.

A comparative analysis reveals that not all solutions are created equal. While some brands may deliver exceptional results, others fall short of expectations. Careful research is essential. Engaging with fellow professionals in the industry can yield valuable insights. Learning from their experiences helps in making informed decisions. Ultimately, the choice of shuttering magnets can significantly affect production efficiency and safety in precast production.