What is a precast concrete fixed magnetic box

Precast concrete magnet is an efficient and convenient fixing device emerging from the process of modern construction industrialization. It cleverly utilizes the principle of magnetism to provide an innovative solution for the fixing and rapid installation of concrete frames.

1.Technical details

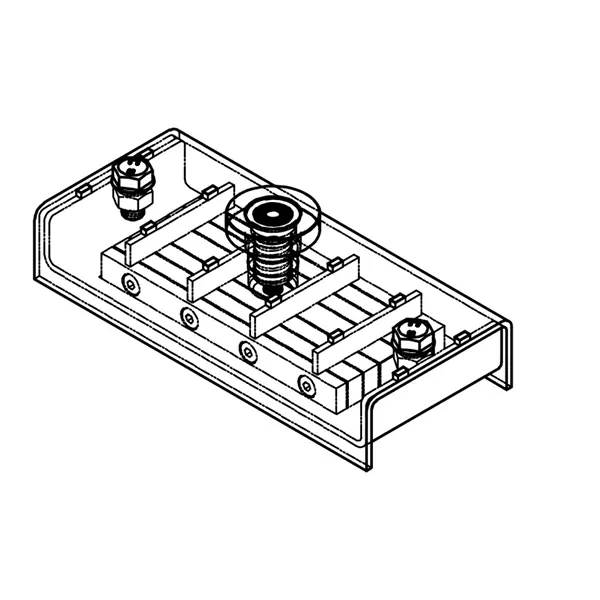

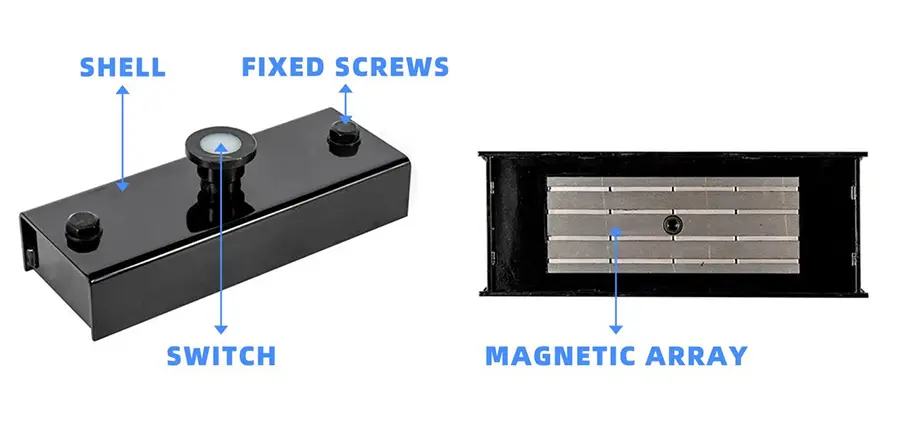

Working Principle: Shuttering Magnet is equipped with high-performance permanent magnets, such as sintered NdFeB magnets, which are capable of generating strong adhesive force. When the magnet box is placed on the designated position on the frame or molding table, press down the switch, the magnetic force works through the magnetic surface and firmly adheres the Framework to the molding table. When it needs to be removed, the switch is pried up by a special tool - pry bar, the distance between the magnetic array and the table surface is increased and the adsorption state is lifted.

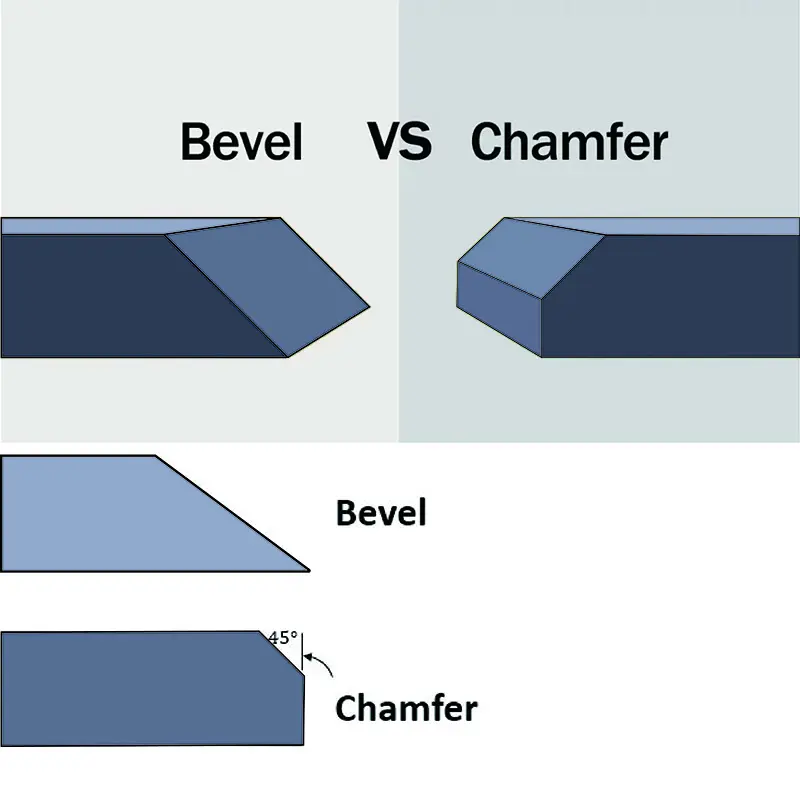

Structural design: Precast magnet usually adopts a hollow and bottomless rectangular structure (similar to a U-shape when viewed from the side), with a magnetic array set at one end and a push button lever and a fixing stud designed at the other end. By operating the push button lever, the activation and release of the magnetic force can be controlled, realizing the fast fixing and dismantling of the Framework. In addition, the magnetic box is equipped with a pressurized plate and gasket (simple adapter to be fixed with screws) to improve the solidity and sealing of the installation.

Material Selection: Precast magnets' shell and internal structural materials need to have good corrosion, abrasion and impact resistance to ensure consistent performance in harsh construction environments. Find out more about materials?

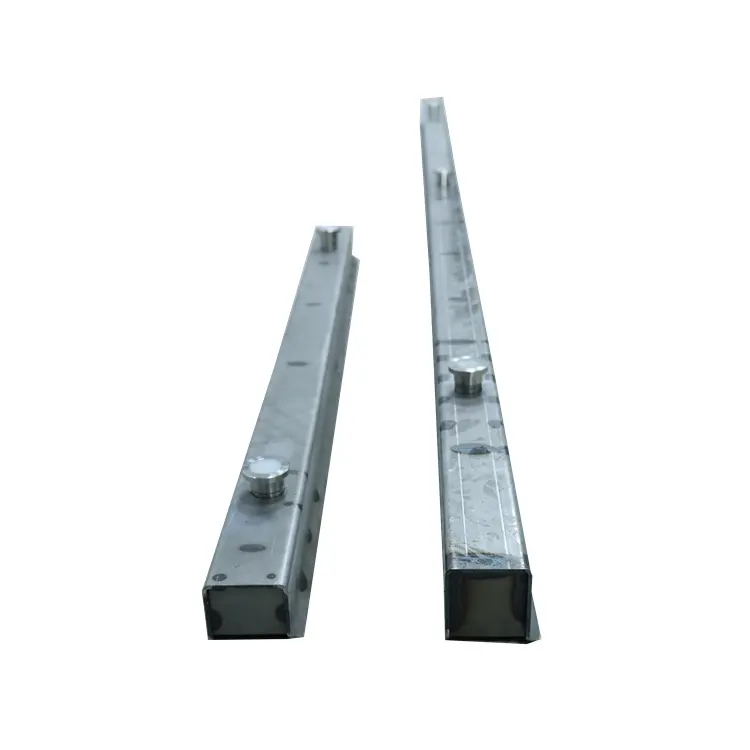

Model selection: QCM series products have carbon steel, stainless steel for your choice, shell thickness 4mm.

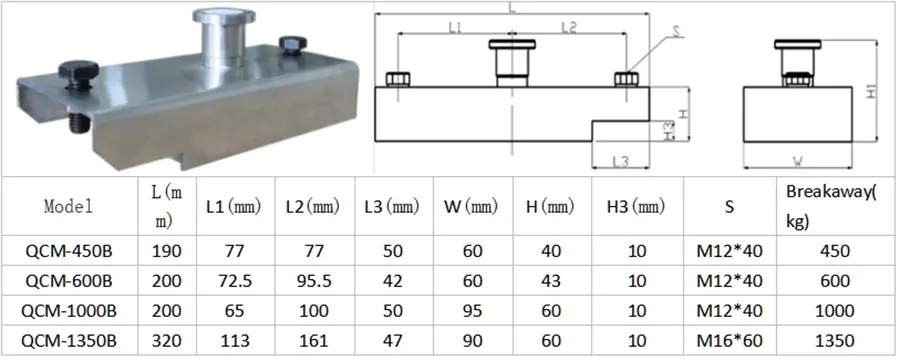

Carbon Steel Enclosures Product Specification Sheet

Stainless Steel Enclosures Product Specification Sheet

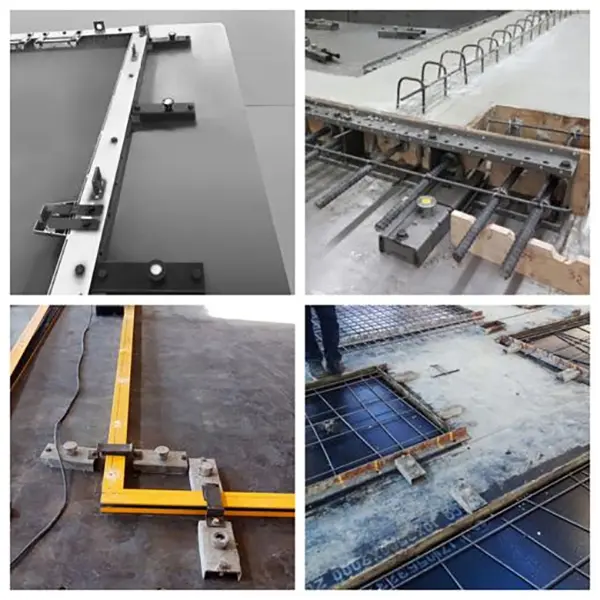

Ⅱ.Magnetic cartridge applications

Template fixing: The adsorption force between the strong NdFeB magnetic core and the steel mold table is transferred to the button switch through the connecting screw to open and close the magnetic box. Single or double side bayonet design, can be directly stuck on the L-shaped angle steel side mold; double side equipped with 8.8 grade high-strength adjustable fastening screws, with the adapter directly down to fix the steel side mold, thus reinforcing the connection between the magnetic cartridge and the angle steel, effectively preventing the mold from shifting.

Multi-material applicability: shuttering boxes are not only suitable for metal molds, but can also be used for wood, rubber and other materials. This versatility makes it widely used in a variety of construction scenarios.

Ⅲ. Advantages

Improve construction efficiency: compared with the traditional mechanical fixing methods such as screws and nuts, Precast concrete magnet is easier and faster to install and dismantle, which effectively reduces the process and time of installing formwork.

Ensure construction quality: it can generate strong and stable magnetic force, firmly adsorb and fix the objects, prevent displacement and deformation during construction, make the formwork uniformly stressed, and ensure the dimensional accuracy and appearance quality of the components.

Reusable: precast magnets have good reusability, a precast magnet can be used repeatedly in multiple projects, which reduces the waste of resources and the generation of construction waste, and conforms to the green and environmental protection construction concept.

Damage-free construction: There is no need to drill holes in the formwork or mold table, which will not cause damage to it, helping to improve the service life of the formwork and mold table and reduce costs.

QCM is the most powerful SHUTTERING MAGNET manufacturer in China, we will sincerely cooperate with you to create customized products with the highest quality to meet your needs.