Magnetic Urethane Chamfer

Composition & Key Properties

Magnetic Urethane Chamfers are engineered using high-performance urethane elastomers combined with NdFeB (neodymium) magnets. This design merges advanced material properties with magnetic adhesion capabilities:

· Durability: Urethane ensures high wear resistance (>200% longer lifespan than rubber) and impact absorption, ideal for construction machinery or high-traffic flooring.

· Magnetic Performance: Embedded NdFeB magnets provide strong adhesion (15–25 N/cm²) to steel, galvanized metal, or iron-based formwork.

· Shore Hardness Options: Two primary grades are standardized:

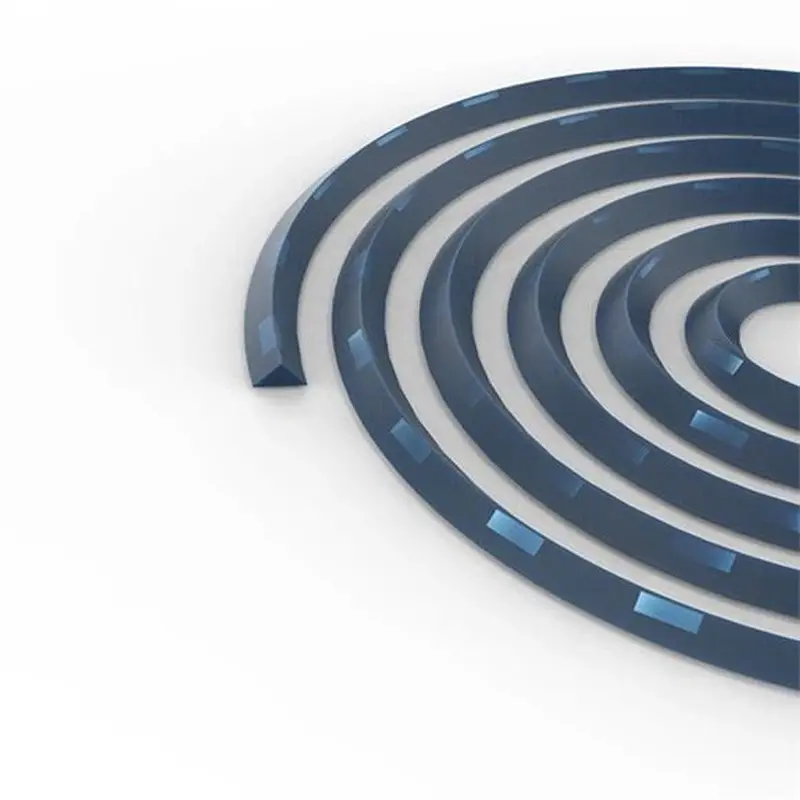

o 60 Shore A: Offers flexibility for curved surfaces or delicate chamfering (e.g., decorative concrete).

o 90 Shore A: High rigidity for heavy industrial use (e.g., ports, airport runways).

· Temperature Stability: Operates from -40°C to 120°C without losing elasticity or magnetic strength (if coated magnets are used).

· Chemical Resistance: Resists oils, solvents, and UV degradation, suitable for outdoor or chemical-exposed environments.

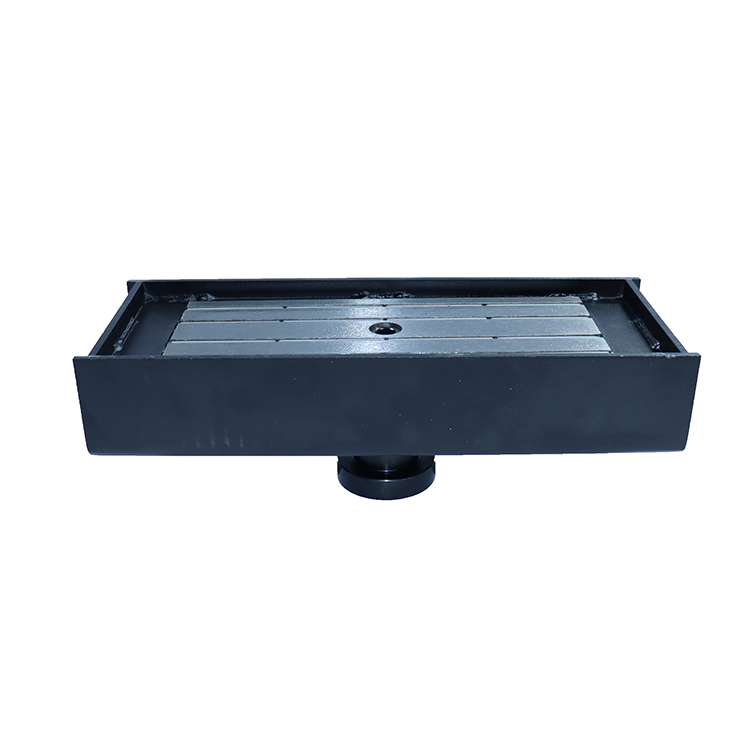

Construction Features

1. Integrated Design: Magnets are fully encapsulated within urethane to prevent corrosion and mechanical damage.

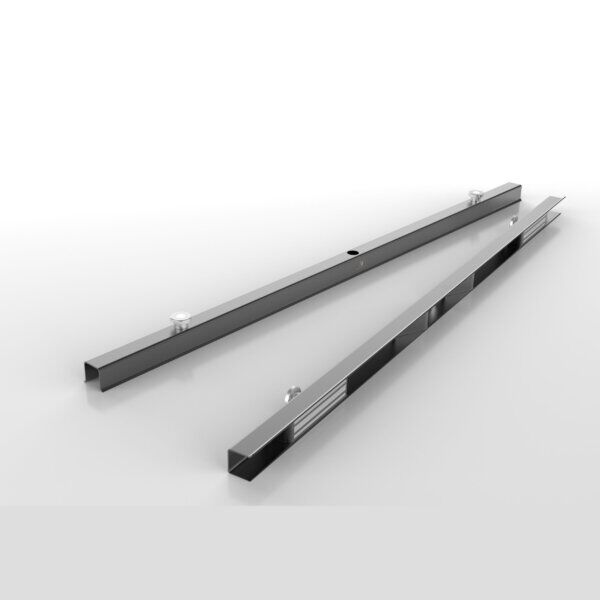

2. Chamfer Dimensions:

o Width: Customizable 50–200 mm (5–20 cm), accommodating edge profiles from fine bevels to broad slopes.

o Length: Standard 1–6 m with modular connectors for seamless curves (e.g., circular columns).

3. Surface Treatments: Textured or smooth urethane surfaces minimize concrete sticking during demolding.

Applications

· Modern Architecture:

o Edge protection for polished concrete floors, terrazzo, or exposed aggregate.

o Rounded edge formation in precast panels (e.g., staircases, facade elements).

· Industrial Infrastructure:

o Heavy-duty chamfering for steel-reinforced concrete in bridges, tunnels, or ports.

o Used with tilt-up wall systems to prevent corner spalling.

· Specialized Use Cases:

o Magnetic adhesion simplifies alignment in 3D-printed concrete mold setups.

o Reusable in modular construction projects (e.g., prefabricated buildings).

Functional Advantages

1. Rapid Installation: Eliminates clamps/screws—3x faster than traditional methods.

2. Repeatable Precision: ≤1 mm edge deviation over 200+ cycles.

3. Cost Efficiency: Reduces labor and material waste by 40% compared to single-use PVC.

4. Sustainability: Recyclable urethane and reusable design align with LEED/GREEN certification standards.

Performance Metrics

Parameter |

60 Shore A Grade |

90 Shore A Grade |

Tensile Strength |

12–15 MPa |

25–30 MPa |

Compression Set |

≤10% (@70°C, 22h) |

≤5% (@100°C, 24h) |

Abrasion Loss |

40 mm³ (DIN 53516) |

20 mm³ |

Magnetic Adhesion |

15–18 N/cm² |

20–25 N/cm² |

Optimized Usage Guidelines

1. Substrate Prep: Ensure metal surfaces are clean, dry, and free of rust or debris.

2. Chamfer Size Selection:

o 50–100 mm: Thin edges (e.g., wall joints, decorative tiles).

o 100–200 mm: Structural edges (e.g., warehouse floors, vehicle ramps).

3. Hardness Pairing:

o 60 Shore A: Flexible for lifted edges or temporary formwork.

o 90 Shore A: Rigid for vibrating screeds or high-pressure pours.

4. Post-Use Maintenance: Clean with pH-neutral detergents; avoid abrasive tools. Store flat to prevent warping.

Industry Adoption Insights

· Europe/Australia: Combined with self-consolidating concrete (SCC) for architectural finishes.

· North America: Preferred in tilt-up concrete warehouses for rapid cycle times.

· Asia: Deployed in prefab housing projects to minimize on-site waste.

| Durometer | Application | Part Code | Height | length |

|

60 Shore |

For Flexible |

QCM-12-8-60 | 1/2'' | 8' |

| QCM-58-8-60 | 5/8'' | 8' | ||

| QCM-34-8-60 | 3/4'' | 8' | ||

| QCM-1-8-60 | 1'' | 8' | ||

| QCM-12-8-60 | 1/2'' | 10' | ||

| QCM-58-10-60 | 5/8'' | 10' | ||

| QCM-34-10-60 | 3/4'' | 10' | ||

| QCM-1-10-60 | 1'' | 10' | ||

| 15x15 | 15mm | 10' |

Why choose QCM?